Threadolet

Today we are gonna to know another model of outlet—-ASTM A105 Threadolet.

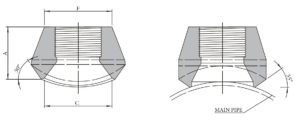

Threadolet is one of integrally Reinforced Connection Branch, which provides an outlet from a larger pipe to a smaller one. Outlet connects onto main pipe by welding, and for branches, it has a female threaded connection to mate.

Pipe Olet is reinforcing pipe fitting for branch pipe connection. Instead of Reducing Tee, reinforcing plate and reinforcing pipe section, it is the most common branch connection method today.

ASTM A105 Threadolet has advantages of safety and reliable, low cost, simple construction, fixed parameters and easy to design and use. It is increasingly widespread used in pipes with high pressure, high temperature, large diameter, thick wall, and replaces traditional branch connection way.

Threadolet

Thread Type

Carbon Steel Threadolet Pressure

Pressure influences weight and price. So the weight of 3000 lb Threadolet and 6000 lb Threadolet are different. Same as Sockolet.

NPT Threadolet

NPT is American thread seal pipe thread, often called national pipe thread standards for short. Thread angle is 60 deg, conicity is 1:16. Both internal (female) and external (male) thread are Rc. It is frequently used in high temperature and high pressure pipeline. FNPT Threadolet is more common.

BSP Threadolet

BSP (British Standard Pipe) is a family of technical standards for screw threads that has been adopted internationally for interconnecting and sealing pipes and fittings by mating an external (male) thread with an internal (female) thread.Thread angle is 55 deg, conicity is 1:16. Internal thread has Rp and Rc two types, while external only has cone-shape R, and Rp-R is more active, and Rc-R is used less.

MSS-SP-97 Threadolet Dimensions

|

Diameter |

Approximate Weight/kg |

||

|---|---|---|---|

|

DN |

NPS | 3000 |

6000 |

|

6 |

1/8 | 0.05 | – |

| 8 | 1/4 | 0.05 |

– |

|

10 |

3/8 | 0.09 | – |

| 15 | 1/2 | 0.17 |

0.47 |

|

20 |

3/4 | 0.22 | 0.65 |

| 25 | 1 | 0.43 |

0.96 |

|

32 |

1-1/4 | 0.61 | 1.28 |

| 40 | 1-1/2 | 0.69 |

2.15 |

|

50 |

2 | 1.1 | – |

| 65 | 2-1/2 | 1.52 |

– |

|

80 |

3 | 2.5 | – |

| 100 | 4 | 4.1 |

– |

What is MSS-SP-97

MSS-SP-97 is the production standard for 90 degree integrally reinforced Forged Branch Outlet Fittings, they all covering the essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements of pipe fittings.

It is developed and approved by the Manufacturers Standardization Society of the Valve and Fittings Industry. Inc.

Manufacturer and the buyer should negotiate before producing special sizes and materials.

Therefore, this standard applies for any type of outlet.

According to statistics, most threadolet is made of carbon steel with 3000 pressure, A105 3000# NPT Threadolet is the most common one. For the purpose of prolong service life, Galvanized Carbon Steel Threadolet is widely used.

Galvanized Threadolet A105

Galvanized Threadolet includes two sorts: Hot Dip Galvanized Threadolet and Cold Dip Galvanized Threadolet ASTM A105.

Hot dip galvanizing is to melt zinc at high temperature and add some auxiliary material, then dip metal pieces into zinc plating bath, make the metal parts attached with a zinc layer. Its advantages are strong corrosion resistance and good zinc coating adhesion and hardness.

Cold galvanizing is the electrolysis of zinc salt solution and then coat the metal parts with it. Generally speaking, it does not require heating, the amount of zinc is very small, and it will fall off easily in moist environment.

Galvanized Threadolet

What is difference between HDG and CDG

HDG has abrasion resistance, cathodic protection, and service life or time to first maintenance. But the surface is not as smooth and exquisite as clod galvanizing, and it is more expensive. So pretty cold galvanizing threadolet is attractive and popular in industry.

Olet Quality Control

Zizi Engineering adopts MSS-SP-97 to manufacture and carry out strict inspection on products.

All Forged Pipe Fittings are inspected before being passed to shipping room. Accurate records are kept of every fitting from initial forging bar through forging, heat treatment, machining, storage and shipment. Every single fitting is traceable to the exact material and process used in its manufacture.

The package of ASTM A105 Threadolet are carton and wooden cases. Customers also can receive a complimentary products and package pictures and certificates.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....