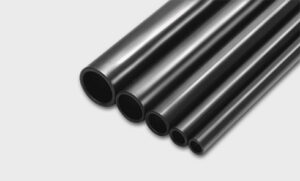

ASME SA213 T5 Tubes

ASTM A213 (ASME SA213) T5 tube is a type of chromium-molybdenum alloy steel pipe. It contains 4.00% – 6.00% Cr and 0.45% – 0.65% Mo. Its UNS name is K41545. It is manufactured in accordance with the standard ASME SA 213/213M “Specification for Ferritic and Austenitic Alloy – Steel Seamless Tubes for Boilers, Superheaters, and Heat Exchangers”. It has has good high-temperature strength, oxidation resistance and corrosion resistance. Therefore, it is often used as seamless steel pipes for boilers, superheaters and heat exchangers.

We manufacture seamless steel pipes with outer diameters ranging from Ф6 to Ф114 mm and wall thicknesses from 0.8 to 10 mm. Our main materials include high-quality carbon steel, alloy steel, low-temperature steel, and corrosion-resistant steel, etc. We strictly control quality at every production stage to ensure all products are thoroughly inspected before delivery. We are certified with TS-A1, ISO9001, ISO14001, OHSAS18001, and pressure equipment licenses recognized in the EU, Germany, and Russia. Feel free to contact us for more information.

ASME SA213 T5 Tubes Standard Scope

This specification covers ferritic and austenitic seamless steel pipes used in boilers, superheaters, and heat exchangers. The steel grades include T5, TP304, etc. The pipe sizes range from an inner diameter of 1/8 inch (3.2 mm) to an outer diameter of 5 inches (127 mm), and the wall thickness ranges from 0.015 inch to 0.500 inch (0.4 mm to 12.7 mm). Other specifications can be provided according to order requirements. This standard is developed in both the International System of Units and the Imperial units, and it is required to be used independently. It also follows the standardization principles of the Technical Barriers to Trade (TBT) Committee of the World Trade Organization.

ASME SA213 T5 Tubes Specification

| Product Name | ASTM A213/ASME SA213 T5 High-pressure Boiler Tubes |

| Standard Specification | Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Tubes for Boilers, Superheaters, and Heat Exchangers |

| Dimensions (mm) | Outer Diameter: 19.05 – 114.3 Wall Thickness: 2.0 – 14 Length: Maximum 16,000 |

| Application | In fossil fuel power plants, it is mainly used for high-temperature applications in superheater and reheater tubes, headers, and steam pipelines (main steam and hot reheat) |

| Inspection and Testing | Chemical composition inspection; Mechanical property tests (tensile strength, yield strength, elongation, flaring, flattening, bending, hardness, impact test); Surface and dimensional tests; Non-destructive testing; Hydrostatic pressure test |

| Surface Treatment | Oil immersion; Varnishing; Passivation; Phosphating; Shot blasting |

ASME SA213 T5 Tubes

ASME SA213 Grade T5 Seamless Alloy Steel Tubes

ASME SA213 T5 Grade Seamless Alloy Steel Heat Exchanger Tubes

ASME SA213 T5 Seamless Alloy Steel Boiler Tubes

ASME SA213 T5 Tubes Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Mo |

| ASTM A213 T5 | MIN | 0.30 | 4.00 | 0.450 | ||||

| MAX | 0.150 | 0.60 | 0.025 | 0.025 | 0.50 | 6.00 | 0.650 |

ASME SA213 T5 Tubes Mechanical Property

| Tensile Strength , MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 415 min | 205 min | 30 min | 163 max |

Alloy T5 Tubes Equivalent Grades

| Standard | Equivalent | |||

| American Society

for Testing and |

American Society

of Mechanical |

European Standard (EN) |

WERKSTOFF NR | UNS |

| ASTMA213 T5 | ASME SA213T5 | EN 10216-2 X11Cr Mo5+l |

1.7362 | K41545 |

ASME SA213 T5 Tubes Heat Treatment

| Grade | UNS Number | Heat Treat Type | Austenitizing/Solutioning Temperature, min or range °F [°C] | Cooling Media | Subcritical Annealing or Tempering Temperature, min or range °F [°C] |

| T5 | K11547 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 to 1350 [650 to 730] |

| T9 | K90941 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1250 [675] |

| T11 | K11597 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 [650] |

| T12 | K11562 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1200 to 1350 [650 to 730] |

| T21 | K31545 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | – |

| T22 | K21590 | Full or isothermal annealnormalize and tempersubcritical anneal | – | – | 1250 [675] |

| T91 | K90901 | normalize and temper | 1900 – 1975 [1040 – 1080] | – | 1350 – 1470 [730 – 800] |

ASME SA213 T5 Tubes Tensile and Hardness Requirements

| Grade | UNS Designation | Tensile

Strength min, kesi [MPa] |

Yield

Strength, min, ksi [MPa] |

Elongation

in 2 in. or 50 mm. min, |

Hardness | |

| Brinell/vickers | Rockwell | |||||

| Low Alloy Steels: | ||||||

| T5b | KS1545 | 60[415] | 30[205] | 30 | 179 HBW/190HV | 89 HRB |

| T9 | K90941 | 60[415] | 30[205] | 30 | 179 HBW/190HV | 89 HRB |

| T12 | K11562 | 60[415] | 32[220] | 30.00 | 163 HBW/170 HV | 85 HRB |

| T23 | K40712 | 74[510] | 58[400] | 20 | 220 HBW/230 HV | 97 HRB |

| T24 | K30736 | 85[585] | 60[415] | 20.00 | 250 HBW/265 HV | 25 HRC |

| T91 | K90901 | 85 [585] | 60 [415] | 20 | 190 to 250 HBW/196 to 265 HV | 90 HRB to 25 HRC |

ASME SA213 T5 Tubes Outside Diameter and Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤190.5 | +0.4/-1.2 | |

| 190.5<OD≤228.6 | +0.4/-1.6 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, mm |

| OD<25.4 | ±0.10 | |

| 25.4≤OD≤38.1 | ±0.15 | |

| 38.1<OD<50.8 | ±0.20 | |

| 50.8≤OD<63.5 | ±0.25 | |

| 63.5≤OD<76.2 | ±0.30 | |

| 76.2≤OD≤101.6 | ±0.38 | |

| 101.6<OD≤190.5 | +0.38/-0.64 | |

| 190.5<OD≤228.6 | +0.38/-1.14 |

ASME SA213 Grade T5 Tubes Wall Thickness and Tolerance

| Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Latest News

- 04 3 月 2026Marking Rules for ASME B16 & B36 Piping ProductsASME standards are the most widely used specifications […]...

- 26 2 月 2026ASME B18.2.1-2012 – The Active StandardASME B18.2.1-2012 is the latest active version of […]...

- 24 2 月 2026EN 1092-1 Loose Plate Flange Type 04What is EN 1092-1 Loose Plate Flange Type 04? EN 1092-1 […]...