Stud Bolts Fluorocarbon Coated

ASTM A193 B7 & B8 / A194 2H Stud Bolts and Nuts Fluorocarbon Coated are widely used since they are pretty, anti-acid and long service life.

What is Stud Bolt

Stud Bolts is externally thread rods without heads. They are usually equipped with two heavy hex nuts at both ends, replacing the usual “bolt and nut” assembly. Their application prominently fields are flange connections, anchor bolting, and general fastening.

Stud Bolt and Nuts are a set, so the description should mention the quantity of nuts, such as stud bolt C/W 2 Units Heavy Hex Nuts PTFE Coated or Sets of Stud Bolts with 02 Hex Nuts Fluorocarbon coated in the inquiries.

Stud Bolt

Bolt and Nut Standard

BS 4882 and ANSI B18.2.1 are the standards which used in manufacture, and standard of nut is ANSI B18.2.2.

BS 4882 is developed and approved by British standards institute, and its full name is Specification for Bolting for Flanges and Pressure Containing Purposes.

ANSI B18.2.1 is an American standard which is specification of square, hex, heavy hex, and askew head bolts and hex, heavy hex, hex flange, lobed head, and lag screws. This is inch series.

ANSI B18.2.2 is Nuts for General Applications: Machine Screw Nuts, Hex, Square, Hex Flange and Coupling Nuts (Inch Series). It is an American standard which developed and approved by American National Standards Committee.

They all covering the essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements of pipe fittings.

Stud Bolts Fluorocarbon Coated Dimensions

The Stud Bolts Fluorocarbon specification is different with pipe fittings, it consists of two parts: diameter and length. Last month we shipped STUDBOLT, 5/8″80MM, UNC, B7,2H,FC to Malaysia.

| Length | 80 MM |

|---|---|

| Inspection, Certificate | ISO 10474-3.1B |

| Material Standard, Nut | ASTM A194 GR. 2H |

| Mat Standard, Stud Bolt | ASTM A193 GR. B7 |

| Coating | FLUOROCARBON |

| Number, Nuts Per Stud Bolt | 2 |

| Design Standard, Nut | ASME B18.2.2 |

| Design Standard, Stud Bolt | BS 4882 |

| Size | 5/8 IN |

| Thread Class Symbol, Bolt | ANSI B1.1 CLASS 2A |

| Thread Class Symbol, Nut | ANSI B1.1 CLASS 2B |

| Type,Nut | UN HEAVY HEXAGONAL |

| Type of Thread | UNC (11 TPI) |

| Basic Data Text | NUTS TO BE SEMI-FINISHED |

Stud Bolt Threads

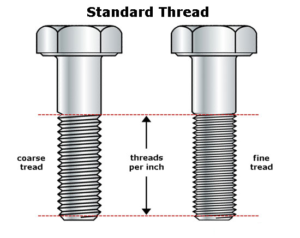

Standard Thread

One client requires stud bolt UNC (11 TPI) and another requires stud bolts M14x55. What does these mean?

They refer to thread types. There are two categories: mertic threads (ISO 965) and unified threads ANSI/ASME B1.1.

M represent Metric threads. So stud bolts M14x55 means it is metric thread, and 14×55 is its size.

Unified threads has three types: Coarse thread series (UNC), Fine thread series (UNF) and customized series(XUN). Customers demand 8UN Studbult more often. UN is the shorten of unified national .

TPI refers to threads per inch, so UNC (11 TPI) means it is 11 threads per inch coarse thread.

Threads Difference

Measured in TPI, UNF and UNC have, respectively, 20 threads per inch and 28 threads per inch.

UN and UNF have same included angle which is 60 deg, the difference between them is the number of threads per inch.

Coarse thread series is the most common thread system and suits for most of screws, bolts and nuts . Diameters one inch and above uses 8UN thread more often.

Material of Stud Bolt and Nuts

Material of Nut usually is ASTM A194 GR. 2H, and Stud Bolt is ASTM A193 GR. B7, they all belong to carbon steel. While for stainless steel material, it is ASTM 193 B8 / B8M.

ASTM A193 GR. B7 Bolt Fluorocarbon Coated

PTFE Bolt&Nut Inspection

The material of A193 B7 Stud Bolts Fluorocarbon is carbon steel, for the purpose of prolong service life, we always use PTFE or fluorocarbon coated (FC).

PTFE coated stud bolts have the advantages of anti-acid, anti-alkali, anti-organic solvent, high temperature resistance, low friction coefficient, self-lubrication, insulation and non-toxic.

Fluorocarbon Coating is an organic coating consisting of solid lubricant dispersed in an organic binder and dissolved in a specially formulated mixture of solvents. It is also corrosion-resistant due to the use of a thermally cured somersetting synthetic binding material.

In order to achieve better protection, some customers chose zinc nickel plating as base coat and PTFE based as top coat.

Zinc-Nickel electroplating is an acid coating that has the property of protect steel, cast iron, malleable iron, copper, and brass. It has good corrosion protection, and functions as a “sacrificial coating”, will rot before the base material.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....