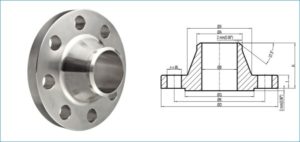

A105 Weld Neck Flanges

ASTM A105 Weld Neck Flange is also known as a High-hub Flange and Tapered Hub Flange. It is the most common type of high pressure flanges.

The size of weld neck flanges bore are machined with the diameter of pipe or pipe fittings. Hence it is important to specify the pipe schedule while buying flanges. It is welded to pipe with full penetration weld. It provides excellent stress distribution through tapered neck. This creates a smooth transition and prevents turbulence at the welding neck.

Weld Neck Flange Types

Regular Weld Neck Flange

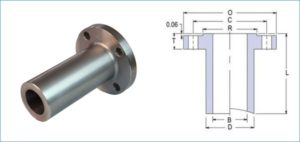

Long Weld Neck Flange

There are regular weld neck flanges and long weld neck flanges. The regular type is used with pipes. The long type is used in process plant.

Both of them provide reinforcement in high pressure and extreme temperature changes applications. It also helps in low cycle fatigue caused by line expansion of other variable forces.

Pipe Flange Seal Type

Pipe Flanges are typically provided with a Raised Face (RF), Flat Face (FF), or Ring Type Joint Facing (RTJ).

Raised Face Weld Neck Flange (RFWN Flange) are one of the most commonly used flange in the piping industry. They are easy to recognize with their long tapered hub that is matched to the wall thickness (bore) of the pipe.

When a raised face is necessary, the standard height is 1/16″while flanges pressure is below 400#. Above 400# flanges, the standard height is 1/4″.

Flange Dimension

Flange Dimension

| Standard | ASME B16.5 |

|---|---|

| Diameter | DN15-600, NPS 1/2-24 |

| Pressure | Class 150, 300, 600, 900, 1500, 2500 |

| Stainless Steel Flange | ASTM A182 F304/304L/304H, F316/316L/316H, F309S/309H, F310/310S/310H, F317/317L |

| Carbon Steel Flange | ASTM A105 Gr. F42, F46, F52, F56, F60, F65, F70 |

| Alloy Steel Flange | ASTM A182 F1, F5, F11, F22, F91 |

| Flange Surface | Black Primer or Galvanized Flange |

Applications of ASME B16.5 Weld Neck Flange

ASME B16.5 Weld Neck Flange are suitable in high pressure, extreme temperatures, shear impact and vibratory stresses area.

What is ASME B16.5

ASME B16.5 is American pipe flange standard. It is limited to flanges and flanged fittings made from cast or forged materials, blind flanges and certain reducing flanges made from cast, forged, or plate materials. Flange Bolting, Flange Gaskets, and Flange Joints are also included in this standard.

ASME B16.5 Flanges

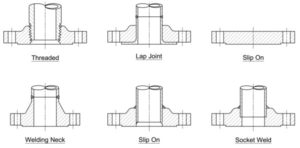

ASTM A105 Flanges include Weld Neck Flange, Slip-on Flange, Socket Weld Flange, Threaded Flange, Blind Flange, Spectacle Flange,Lap-Joint Flange, Reducing Flange,Groove Flange, Tongue Flange in carbon steel, alloy steel and stainless steel. The mostly common is A with good performance and price. The heat treatment is normalizing at 1550 to 1770 F.

ASTM A105 Chemical Composition, %

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.35 | 0.1-0.35 | 0.6-1.05 | 0.035 | 0.04 |

ASTM A105 Mechanical Properties

| Tensile Strength

min |

Yield Point

min |

Reduction

of Area min |

Hardness

HB max |

|---|---|---|---|

| 485 MPa | 250 MPa | 30% | 187 |

A105N Flanges Heat Treatment

It can be performed includes normalizing, quenching, tempering, stress-relieving, soft annealing, normalizing and tempering, and isothermal annealing.

- Annealing: The purpose is to get an organization that is close to balanced state. Its Cooling rate is slow.

- Stress-relieving: Eliminate the stress generated during processing and improve the crack resistance and toughness of the weld. It has integrated post-weld heat treatment and partial post-weld heat treatment two types.

- Normalizing: Cooling rate is faster than annealing. The strength, hardness and toughness of fittings after normalizing are higher than annealing.

- Quenching: Austenite can be transformed into Martensite during this processing. Martensitic workpieces have high hardness, but have poor toughness, and large internal stress. They are prone to cracks.

- Tempering: Its purpose is to reduce the stress of the material and improve the toughness.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....