On April 17, 2025, an old customer from China sent us an inquiry for ASTM A815 UNS S31803 Butt Weld Pipe Fittings, which is another manifestation of the trust between the two parties over the years. We immediately conducted a detailed analysis based on the drawings and technical requirements provided by the customer to ensure that we can provide accurate and professional solutions in the shortest time.

ZIZI is a professional manufacturer and processor of pipes and fittings, dedicated to providing high-quality products for core sectors such as chemical, petroleum, natural gas, water conservancy, electric power, and marine engineering. We offer a comprehensive range of pipes and fittings, including seamless pipes, welded pipes, butt weld fittings, high-pressure forged fittings, and flanges. Crucially, we also possess strong capabilities in producing machined parts, allowing us to customize products to meet specific client requirements. Our materials expertise covers a wide array, including carbon steel, stainless steel, alloy steel, low-temperature steel, duplex steel, and nickel-based alloys, ensuring we can satisfy demanding application needs across various harsh operating conditions.

Purchase List

| ITEM | DESCRIPTION | QUANTITY | UNITS |

| 1 | Elbow/curva 90° LR SMLS A815 UNS S31803 Sch.40S diam.: 2 1/2 | 6 | PCS |

| 2 | Elbow/curva 90° LR SMLS A815 UNS S31803 Sch.40S diam.: 4″ | 10 | PCS |

| 3 | Conc Red/rid. conc. SMLS A815 UNS S31803 Sch.40S diam.: 2″ x 1 1/2″ | 5 | PCS |

| 4 | Conc Red/rid. conc. SMLS A815 UNS S31803 Sch.40S diam.: 2 1/2″ x 2″ | 5 | PCS |

| 5 | Conc Red/rid. conc. SMLS A815 UNS S31803 Sch.40S diam.: 4″ x 2″ | 4 | PCS |

| 6 | Cap/Fondo bomb. Smls A815 S31803 Sch.40S diam.: 2 1/2″ | 4 | PCS |

| 7 | Cap/Fondo bomb. Smls A815 S31803 Sch.40S diam.: 4″ | 4 | PCS |

ASTM A815 UNS S31803 Pipe Fitting Dimension Inspection

Outer Diameter (OD): Measure the outer diameter at both ends of the fitting to ensure it meets tolerance requirements.

Wall Thickness (WT): Measure the wall thickness at various points on the fitting (especially the outer and inner arcs of elbows, and the transition sections of reducers) to ensure it falls within the permissible deviation.

ASTM A815 UNS S31803 Pipe Fittings Specification

| Specifications | ASTM A815 / ASME SA815 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Grades | Duplex S31803, S32205 |

| Size | 1/2” NB to 24″NB in |

| Type | Seamless / Welded / Fabricated |

| Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

ASTM A815 UNS S31803 Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| ASTM A815 UNS 31803 | MIN | |||||||||

| MAX | 0.03 | 2.0 | 0.030 | 0.020 | 1.0 | 23 | 6.5 | 3.5 | 0.20 |

ASTM A815 UNS S31803 Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % | HARDNESS |

| ASTM A815 UNS 31803 | 620 min | 450 min | 20 min | 290 max |

Equivalent Grades of ASTM A815 Duplex Steel Buttweld Fittings

| JIS | KS | UNS | ISO | DIN EN/DIN W-Nr. | EN |

| SUS 329J3L | STS 329J3L | S31803 | X2CrNiMoN 22-5-3 | X2CrNiMoN 22-5-3 | 1.4462 |

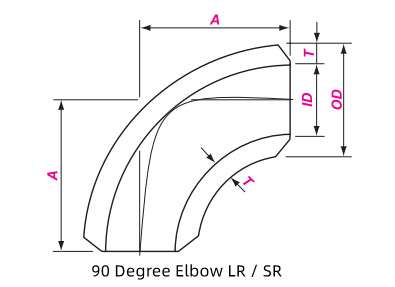

Duplex S31803 Buttweld Pipe Elbow Dimension

| DN | NPS | OD | A-LR | A-SR |

| 15 | 1/2 | 21.3 | 38 | 25 |

| 20 | 3/4 | 26.7 | 38 | 25 |

| 25 | 1 | 33.4 | 38 | 25 |

| 32 | 1 1/4 | 42.2 | 48 | 32 |

| 40 | 1 1/2 | 48.3 | 57 | 38 |

| 50 | 2 | 60.3 | 76 | 51 |

| 65 | 2 1/2 | 73 | 95 | 64 |

| 80 | 3 | 88.9 | 114 | 76 |

| 90 | 3 1/2 | 101.6 | 133 | 89 |

| 100 | 4 | 114.3 | 152 | 102 |

| 125 | 5 | 141.3 | 190 | 127 |

| 150 | 6 | 168.3 | 229 | 152 |

| 200 | 8 | 219.1 | 305 | 203 |

| 250 | 10 | 273 | 381 | 254 |

| 300 | 12 | 323.8 | 457 | 305 |

| 350 | 14 | 355.6 | 533 | 356 |

| 550 | 22 | 559 | 838 | 559 |

| 600 | 24 | 610 | 914 | 610 |

| 650 | 26 | 660 | 991 | 660 |

| 700 | 28 | 711 | 1067 | 711 |

| 750 | 30 | 762 | 1143 | 762 |

| 800 | 32 | 813 | 1219 | 813 |

| 850 | 34 | 864 | 1295 | 864 |

| 900 | 36 | 914 | 1372 | 914 |

| 950 | 38 | 965 | 1447 | 965 |

| 1000 | 40 | 1016 | 1524 | 1016 |

| 1050 | 42 | 1067 | 1600 | 1067 |

| 1100 | 44 | 1118 | 1676 | 1118 |

| 1150 | 46 | 1168 | 1753 | 1168 |

| 1200 | 48 | 1219 | 1829 | 1219 |

| 1300 | 52 | 1321 | 1981 | 1321 |

| 1400 | 56 | 1422 | 2134 | 1422 |

| 1500 | 60 | 1524 | 2286 | 1524 |

| 1600 | 64 | 1626 | 2438 | 1626 |

| 1700 | 68 | 1727 | 2591 | 1727 |

| 1800 | 72 | 1829 | 2743 | 1829 |

| 1900 | 76 | 1930 | 2896 | 1930 |

| 2000 | 80 | 2032 | 3048 | 2032 |

Application Areas

Oil and gas industry: especially offshore platforms, gas gathering pipelines, crude oil and natural gas processing equipment, dealing with corrosive environments with high chloride ions and hydrogen sulfide.

Chemical and petrochemical industries: chlor-alkali industry, fertilizer production, acid treatment, seawater cooling systems, etc., dealing with various highly corrosive chemical media.

Desalination: Pipeline, pump and valve systems, resisting corrosion from high-concentration chloride seawater.

Pollution control equipment: Flue gas desulfurization (FGD) systems, handling hot and humid flue gas containing chlorides and sulfur oxides.

Pulp and paper industry: Equipment and pipelines in bleaching plants, resisting corrosion from chlorine-containing bleaching agents.

Structural applications: Structural components that require high strength and corrosion resistance.

Latest News

- 04 3 月 2026Marking Rules for ASME B16 & B36 Piping ProductsASME standards are the most widely used specifications […]...

- 26 2 月 2026ASME B18.2.1-2012 – The Active StandardASME B18.2.1-2012 is the latest active version of […]...

- 24 2 月 2026EN 1092-1 Loose Plate Flange Type 04What is EN 1092-1 Loose Plate Flange Type 04? EN 1092-1 […]...