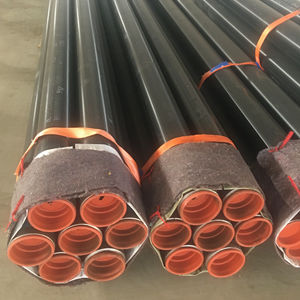

API 5L X46MS PSL2 PIPE

API 5L X46MS PIPE

We are manufacturer of API 5L PIPE and providing API 5L X46MS PSL2 168.3 X 9.53mm X 12.2m with 3LPE Coating for Qatar.

It is a welded carbon steel pipe. It would be spiral or Longitudinal welding. They are used in diferent occasions and situations. The dimension and length is available in a wide ranges for clients.

We are manufacturer and exporter of seamless and welded API 5L pipes. We also supply diverse coatings for carbon steel pipes such as galvanized coating and black primer.

API 5L X46 PSL2 Pipe Specification

Size: 168.3×9.53mm

Material: API 5L X46MS

Grade: PSL2

Surface: 3LPE

API 5L Material

API 5L is a standard specification for line pipe which used to conveying gas, water and oil in both the oil and natural gas industries. It covers some grades of carbon steel for seamless or welded line pipe.

API 5L Pipe Grades

A25, A25R, A, B, X42, X46, X52, X56, X60, X65, X70, X80

Specification Level

PLS1, PLS2, they shall be placed immediately after the grade sykmbol.

API 5L X46 PSL2 Chemical Composition

| Cb | Si | Mnb | P | S | V | Nb | Ti |

|---|---|---|---|---|---|---|---|

| 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 |

API 5L X46 PSL2 Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 435 | 320 | f |

3LPE Pipe

Threr are three layers in 3LPE coated API 5L X46MS Pipe.

Layer 1: A corrosion proective layer. Mainly is fusion bonded expoxy, it will bonding wiht the steel surface.

Layer 2: Copolymer adhesive layer. Copolymer adhesive is a maleic anhydride grafed polyethylene compound.

Layer 3: This layer is for physical protection and consists of polyethylene.

API 5L X46MS Pipe usually provided with 3LPE coating.

Carbon Steel Welded Pipe Quality Control

Surface

Clear Marking and fin appearance. The marking should conver item, diameter, thickness, length, material, coating and heat No.

Dimension

Measure the diameter, thickness and lenght of API 5L X46 PSL2 pipes, make sure they are in tolerance.

Material

Test if the chemical composition and mechanical properties are qualified.

- Hydrostatic test to ensure it’s leak-proof.

- Bend test: no cracks or opening of the weld shall occur.

- Flattening test

Certificate

- CE, ISO, TEST REPORT, Stamp mill test certificate

Third Party Ispection

BV, SGS, LR, DNV, ABS

此站点遇到了致命错误。