Butt Weld Cap

Butt Weld Cap

We are manufacturer of butt weld cap and supplies all schedules in kinds of materials such as carbon steel, stainless steel, alloy steel. Zizi produces pipe caps in ASME, DIN, JIS and other required standards.

Pipe cap is one of the common used pipe fittings for stoping fluid by covering at the pipe end. It is available in butt weld type, socket weld type and threaded type, and buttweld cap is more popular in view of the good performance, stable connection and large dimension selection range.

Here some details of buttweld pipe caps: Dimensions, Materials, Weigh Chart, Manufacturing Process and Features.

Pipe Cap ASME B16.9 Dimensions

- Size: from 1/2″ -48″ (DN15–DN1200)

- Thickness: Sch10S, Sch20, STD, Sch40, XS, Sxh 80, Sch120, Sch 140, Sch160, XXS.

- Form: Welded, Seamless

- Standard: ASME B16.9 ASME B16.25

- Material: Carbon Steel, Stainless Steel, Duplex Stainless Steel, Alloy Steel,Monel, Nickel, Inconel, Hastalloy

- Finish:Galvanized or Black,PE and Pickled

- Packing: Carton box, wooden box & pallet

Material Grades:

Carbon Steel Butt Weld Cap: ASTM A234 WPB, A420 WPL3,WPL6, WPL9,WPHY42, WHPY52, WPHY60, WHPY65, WPHY70.

Stainless Steel Pipe Cap: ASTM A403 WP304/304L, 316/316L, 321, 310S, 317,347

Duplex Stainless Steel BW Cap: UNS S31803, S32205, S32550, S32750, S32760

Alloy Steel BW Pipe Cap: ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Nickel Alloy BW End Cap: ASTM / ASME SB 111 UNS NO. C10100, C10200 , C10300 , C10800 , C12000, C12200, ASTM / ASME SB 466

Copper Alloy Steel Pipe Cap: UNS NO. C70600 ( CU -NI- 90/10) , C71500 ( CU -NI- 70/30)

Steel Pipe Cap Weight Chart

| Steel Pipe Cap Weight/kg | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Size | SCH 20 | STH | SCH 40 | XS | SCH 80 | SCH 120 | SCH160 | |

| DN | NPS | |||||||

| 15 | 1/2 | 0.04 | 0.04 | 0.06 | 0.06 | 0.08 | ||

| 20 | 3/4 | 0.05 | 0.05 | 0.07 | 0.07 | 0.11 | ||

| 25 | 1 | 0.12 | 0.12 | 0.16 | 0.16 | 0.22 | ||

| 32 | 1 1/4 | 0.16 | 0.16 | 0.22 | 0.22 | 0.28 | ||

| 40 | 1 1/2 | 0.19 | 0.19 | 0.26 | 0.26 | 0.36 | ||

| 50 | 2 | 0.26 | 0.26 | 0.36 | 0.36 | 0.57 | ||

| 65 | 2 1/2 | 0.44 | 0.44 | 0.59 | 0.59 | 0.80 | ||

| 80 | 3 | 0.73 | 0.73 | 1.08 | 1.08 | 1.48 | ||

| 90 | 3 1/2 | 1.07 | 1.07 | 1.51 | 1.51 | |||

| 100 | 4 | 1.30 | 1.30 | 1.85 | 1.85 | 2.40 | 2.91 | |

| 125 | 5 | 2.10 | 2.10 | 3.00 | 3.06 | 4.07 | 5.09 | |

| 150 | 6 | 3.19 | 3.19 | 4.60 | 4.93 | 6.41 | 8.20 | |

| 200 | 8 | 4.45 | 5.72 | 5.72 | 8.20 | 8.88 | 12.80 | 16.10 |

| 250 | 10 | 6.89 | 10.10 | 10.10 | 13.00 | 16.40 | 23.30 | 31.00 |

| 300 | 12 | 9.75 | 13.90 | 15.90 | 18.50 | 26.90 | 39.00 | 51.20 |

| 350 | 14 | 14.60 | 17.60 | 20.50 | 23.00 | 35.00 | 51.10 | 65.70 |

| 400 | 16 | 18.30 | 22.00 | 29.40 | 28.60 | 49.70 | 71.70 | 93.80 |

| 450 | 18 | 23.40 | 28.00 | 42.20 | 36.70 | 70.40 | 103.00 | 134.00 |

| 500 | 20 | 35.10 | 33.80 | 55.60 | 44.60 | 96.50 | 141.00 | 184.00 |

| 550 | 22 | 42.70 | 39.50 | 52.50 | 128.00 | 185.00 | 242.00 | |

| 600 | 24 | 49.70 | 47.60 | 91.20 | 63.00 | 162.00 | 240.00 | 311.00 |

Buttweld Fittings Manufacturing Process

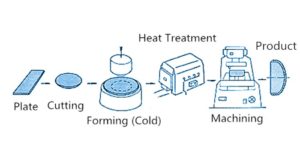

There are mainly tow ways for buttweld fittings manufacturing: cold drawn and hot forming.

The general process are as follows:

- Material preparing

- Cutting: Cutting pipes or plate into certain shape or length

- Forming: Form materials into shapes such as BW Pipe cap, 90 degree elbow, reducing tee. Cold drawn product will be formed directly into specific shape by hammers, mechanical presses or upsetters. Hot forming process will heating the material first and then form it.

- Heat Treatment: It is the process of heating and cooling metals to change the microstructure and to bring out the physical and mechanical properties that make metals more desirable.

- Machining: This process is using sharp cutting tools to trim shapes and prepare ends.

- Inspection and Test: In accordance to standards inspect the size, material and appearance.

- Coating as requirement

Butt Weld Pipe Cap Features

Compared to other type pipe caps, butt weld pipe cap has advantages of

- Low Cost

- Large size range

- High Leak Proof

- Welded connection offers more robust connection

- Welded construction permits greater freedom in designing a layout; this system uses less space, is more compact, and has greater strength.

Related Products

Weld Neck Flange

We are manufacturer of weld neck flange in kinds of materials such as carbon steel, stainless steel, alloy steel.

A333 Gr 6 Alloy Steel Pipe

We supply ASTM A333 Gr 6 alloy steel pipe for industrial use in both seamless and welded.

Hex Head Plug

We are manufacturer of hex head plug and supplies NPT BSPP in kinds of materials such as carbon steel, stainless steel, alloy steel.Product Categories

- Pipe

- Fittings

- Butt Weld Fittings

- Socket Weld Fittings

- Threaded Fittings

- Steel Pipe Elbow

- Steel Pipe Bend

- Steel Pipe Coupling

- Steel Pipe Cap

- Steel Pipe Nipple

- Steel Pipe Union

- Equal Tee

- Reducing Tee

- Cross Tee

- Stub End

- Weldolet

- Sockolet

- Threadolet

- Pipe Olet

- Threaded Plug

- Threaded Bushing

- Concentric Reducer

- Eccentric Reducer

- Flange Gasket

- Flange