Galvanized Socket Weld Elbow

Galvanized 90 Degree Elbow

Hot dipped galvanized socket weld elbow dimensions is from 1/8” to 4”, class 3000, class 6000 and class 9000. Socket weld fittings have exceptional strength of welded joints.

Socket weld elbow has 90° and 45° forms. They offer a strong and speed connect which has similar strength to welded fittings, its also a economical connection way than butt welding.

Hot dip galvanizing is a prevalent coating for carbon steel forged fittings because the coating is even and thicker than cold galvanizing and has better corrosion resistance.

Zizi is manufacture and exporter of galvanized steel pipe fittings and we hold a large stock of 90 degree galvanized socket weld elbows.

Product Attributes of Galvanized Socket Weld Elbow

Type: 90° Elbow

End: Socket Weld

Size: 2” Class 3000

Material: ASTM A105N

Standard: ANSI / ASME B16.11

Surface Treatment: Hot Dip Galvanizing

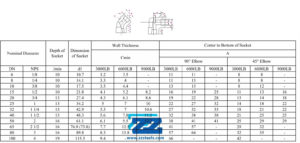

Socket Weld Elbow Dimensions

Supply Range for Galvanized Socket Weld Elbow

| Standard | ASME B16.11, BS 3799 |

|---|---|

| Diameter | 1/8″, 1/4″, 3/8″, 1/2″, 1/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″ |

| Pressure | Class 3000, Class 6000 and Class 9000 |

| Stainless Steel Socket Weld Elbow | ASTM A182 F316/316L, F304/304L/304H, F317, F321, F310, F347 |

| Carbon Steel Galvanized Socket Weld Elbow | ASTM A105 / 105N, A350 LF2/LF3,A694 F52, F60, F65, F70 |

| Alloy Steel Socket Weld Elbow | ASTM A182 F1, F5, F9, F11, F12, F22, F91 |

Package of 90° Socket Weld Elbow

- Anti-rust oil

- Plastic foam

- Carton box

- Wooden cases

Forged Pipe Fittings Manufacturer Process

What are Socket Weld Fittings

According to the order in the video, socket weld fittings include Tee, Cross, Union, Cap , 45 degree elbow, gal 90 degree elbow, Half Coupling, Full Coupling.

Usage of Socket Weld Pipe Fittings

Gal socket weld elbow suits for small diameter high pressure pipe systems.

- Oil and Gas

- Chemical

- Power Generation

- Shipbuilding

- Environment Control

ASTM A105N Propetries

ASTM A105N Socket Weld Elbow Chemical Composition

| C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.15 | 0.6-1.05 | 0.035 | 0.04 | 0.1 | 0.3 | 0.12 |

ASTM A105NSocket Weld Elbow Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 485 (Mpa) | 250 (Mpa) | 30 (%) |

此站点遇到了致命错误。