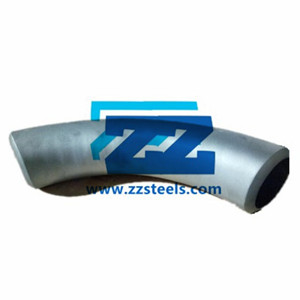

Stainless Steel 3D Bends 90 Degree

Stainless Steel Pipe Bend

Leading manufacturer Zizi offers seamless 316 stainless steel 3D bends in various degree and dimensions. 16″ 90° bend supplied to Chile in best price.

Pipe bend is a basic buttweld pipe fitting that similar to pipe elbow for changing the directions of flow. The angle of pipe bend is diverse, usually is 45 degree, 90 degree or 180 degree, other degrees like 35 degree, 60 degree also can be offered as clients requirements. They are available in different materials as well, stainless steel bends are one popular type with high strength and long service life.

Zizi is China leading supplier of steel pipe fittings and flanges, we offer products in customized sizes and store a large quantity of common used sizes.

Shipment of 16” 90 Degree bend

Product: 90 Degree Pipe Bend

Sizes: 16” Sch 40

Radius: R= 3D

Type: Seamless

Material: Stainless steel 316 / ASTM A403 WP316

Package: Plastic film and wooden pallet for 16” stainless steel 3D bend

Lead Time: 10 Days are ready for shipping

Document: CI, PL, CO, BL, MTC

Inspection of Stainless Steel 3D Bend

- Marking: Clear, Correct, beautiful.

- Surface: Even and Smooth.

- Dimensions: Be in tolerance

- Material: Check the chemical composition of stainless steel 316.

Material for 90 Degree 3D Bend

ASTM A234 WPB, A106B, A860 WPHY42, 52, 60, 65, 70, A420 WPL 3 / 6 / 9

Stainless Steel 3D Bend

ASTM A403 WP304/304L/304H, WP316/316L, WP310, WP317, WP321, WP309, WP347

Nickel Alloy 3D Bend

ASTM / ASME SB 336, SB 564 UNS2200 (NICKEL 200) , UNS2201 (NICKEL 201 ) , UNS4400 (MONEL 400 ), UNS6600 (INCONEL 600 ) , UNS6601 (INCONEL 601) , UNS6625 (INCONEL 625) , UNS10276 (HASTELLOY C 276)

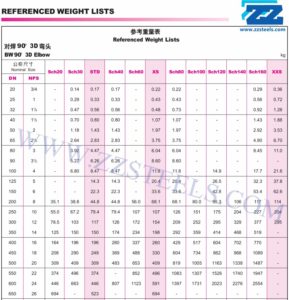

How to Calculate the Weight of Steel Bends?

Weight formula: 0.0433 x (D-T) x T x R x θ / 100000 + L

- D = Outside Diameter

- T = Thickness

- R = Bend Radius

- θ = Bend Angle

- L = Weight of Double Sides Straight Length

Weight Chart

Differences Between Pipe Elbow and Pipe Bend

- Radius

The maximum radius of pipe elbow is 1.5D, which means radius is 1.5 times of diameter. While minimum radius of pipe bend is 1.5D.

Because of the larger radius, stainless steel 3D bend offers more smooth direction change than elbows.

- Length

The straight length of pipe elbow is shorter than pipe bends.

Straight length of stainless steel 3D bends are usually between 300mm to 1500mm.

Stainless Steel 316 Properties

ASTM A403 WP304 Chemical Composition

| C | Mn | Si | P | S | Ni | Cr |

|---|---|---|---|---|---|---|

| 0.08 | 2.0 | 1.0 | 0.045 | 0.03 | 8-11 | 18-20 |

ASTM A403 WP304 Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 40 (%) |

此站点遇到了致命错误。