Butt Weld Fittings

Butt Weld Elbow is a basic fitting for changing direction of water, gas and oil pipelines. It is important to get the approximate weight which determines the cost. So how to calculate elbow weight in kg?

What Factors Influence Butt Weld Elbow Weight?

To know the elbow weight, we should know which factors decide weight.

Many factors influence its weight, the most influential factors are diameter, wall thickness, radius, and elbow degree.

Next, I will show you how to calculate weight based on those factors.

How to Calculate 90 Degree Elbow Weight?

People mainly use two ways to calculate the Butt Weld Pipe Fittings.

- Calculate according to the weight formula.

- Get the value from weight chart.

No matter which way you choose, the butt weld elbow weight is calculated based on 90 Degree. Because 90 Degree Carbon Steel Elbow is the most common type.

Calculate 90 Degree Steel Elbow by Formula

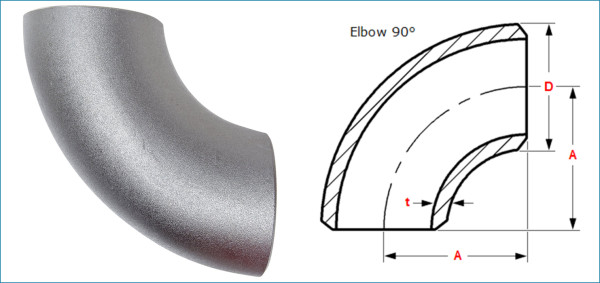

This method is a little difficult, because we should know some exact values in mm. They are outside diameter, wall thickness and bend radius. Unfortunately, it is not the unit we usually use to measure.

The formula of butt weld elbow or bend as below:

W=0.387 * S*(D – S) * R / 1000

Note:

- W means Weight. The unit is Kg/piece.

- S refers to wall thickness schedule.

- D is nominal diameter.

- R is Bend Radius. LR=1.5D, SR=1D.

For example, 1 inch 90 Degree LR Elbow Sch40 A234 WPB, From above information, we can get LR=1.5D, D=33.4mm, S=3.38mm, W = 0.387 * 3.38 * (33.4 – 3.38) * 1.5 * 33.4 / 1000 = 1.97. So it is 1.97 Kg per piece.

This formula is suitable for steel pipe bend as well.

Calculate 90 Degree Steel Pipe Elbow by Chart

Compared to formula, calculating by weight chart is a fast and easy way that is very useful in practice, the things you need to do is to find the value according to elbow dimensions. But we still use formula because it can be used for special thickness that we can’t find in the chart.

This chart are made based on Carbon Steel 90 Degree Long Radius Butt Weld Elbow Fittings, but it is also suitable for stainless steel and alloy steel pipe in views of they are little different in weight. 45 degree steel elbow is calculated in the same way as formula, and short radius elbow is calculated by a simple multiplication.

90 Degree Long Radius Butt Weld Elbow Weight in kg

| DN | NPS | 10S | 20 | STD | 40 | XS | 80 | 100 | 120 | 140 | 160 | XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 1/2 | 0.06 | 0.08 | 0.08 | 0.1 | 0.1 | ||||||

| 20 | 3/4 | 0.08 | 0.11 | 0.11 | 0.13 | 0.13 | ||||||

| 25 | 1 | 0.13 | 0.15 | 0.15 | 0.21 | 0.21 | 0.25 | 0.26 | ||||

| 32 | 1 1/4 | 0.21 | 0.25 | 0.25 | 0.36 | 0.36 | 0.42 | 0.64 | ||||

| 40 | 1 1/2 | 0.3 | 0.39 | 0.39 | 0.52 | 0.52 | 0.65 | 0.93 | ||||

| 50 | 2 | 0.47 | 0.66 | 0.66 | 0.96 | 0.96 | 1.33 | 1.61 | ||||

| 65 | 2 1/2 | 0.79 | 1.37 | 1.37 | 1.8 | 1.8 | 2.33 | 3.43 | ||||

| 80 | 3 | 1.16 | 2.19 | 2.19 | 2.87 | 2.87 | 3.83 | 5.25 | ||||

| 90 | 3 1/2 | 1.55 | 2.96 | 2.96 | 4.06 | 4.06 | ||||||

| 100 | 4 | 2.02 | 4.13 | 4.13 | 5.6 | 5.6 | 8.03 | 10.2 | ||||

| 125 | 5 | 3.46 | 6.89 | 6.89 | 9.62 | 9.62 | 14.7 | 17.6 | ||||

| 150 | 6 | 4.98 | 10.7 | 10.7 | 16.5 | 16.5 | 19.5 | 24.2 | 23.1 | |||

| 200 | 8 | 9.57 | 16.5 | 21.6 | 21.6 | 31.6 | 31.6 | 36.3 | 43.3 | 48.3 | 53.3 | 51.7 |

| 250 | 10 | 16.7 | 25.8 | 37 | 37 | 49.9 | 60.7 | 68.6 | 79.5 | 92.8 | 103 | 92.8 |

| 300 | 12 | 25.9 | 36.1 | 56 | 61 | 71.6 | 97.4 | 115 | 134 | 149 | 171 | 134 |

| 350 | 14 | 34.7 | 60.2 | 71.4 | 85.1 | 92 | 139 | 163 | 188 | 212 | 236 | |

| 400 | 16 | 45.4 | 78 | 93.6 | 121 | 121 | 200 | 235 | 274 | 319 | 350 | |

| 450 | 18 | 56.2 | 87.7 | 119 | 176 | 153 | 287 | 334 | 392 | 440 | 495 | |

| 500 | 20 | 82.2 | 147 | 147 | 232 | 190 | 396 | 457 | 528 | 609 | 676 | |

| 550 | 22 | 99.6 | 178 | 178 | 230 | 515 | 594 | 694 | 790 | 886 | ||

| 600 | 24 | 136 | 212 | 212 | 377 | 275 | 635 | 786 | 919 | 1033 | 1160 |

Formulas for 90 Degree Short Radius Elbow

- 90 Degree Short Elbow = 90 Degree Long Butt Weld Elbow * 0.9

- W=0.387 * S*(D – S) * R / 1000

For example, you have a DN100 Sch10S 90 Degree Long Radius A312 Gr.316 Elbow, according to the following chart, its weight is 2.02 Kg.

45 Degree Elbow Formulas

- 90 Degree Short Elbow Weight = 90 Degree Butt Werld Elbow Weight * 0.56

So the 45 degree elbow in above same size is 2.02 * 0.56 = 1.13 Kg.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....