Buttweld Fittings Manufacturer

Zizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, cap, reducer and stub end in max diameter 80″.

Stainless steel fittings have higher chrome and nickel content so that they have great corrosion resistance and mechanical properties. We have an extensive inventory of stainless steel buttweld fittings, including seamless and welded types.

Buttweld Pipe Fittings Catalog

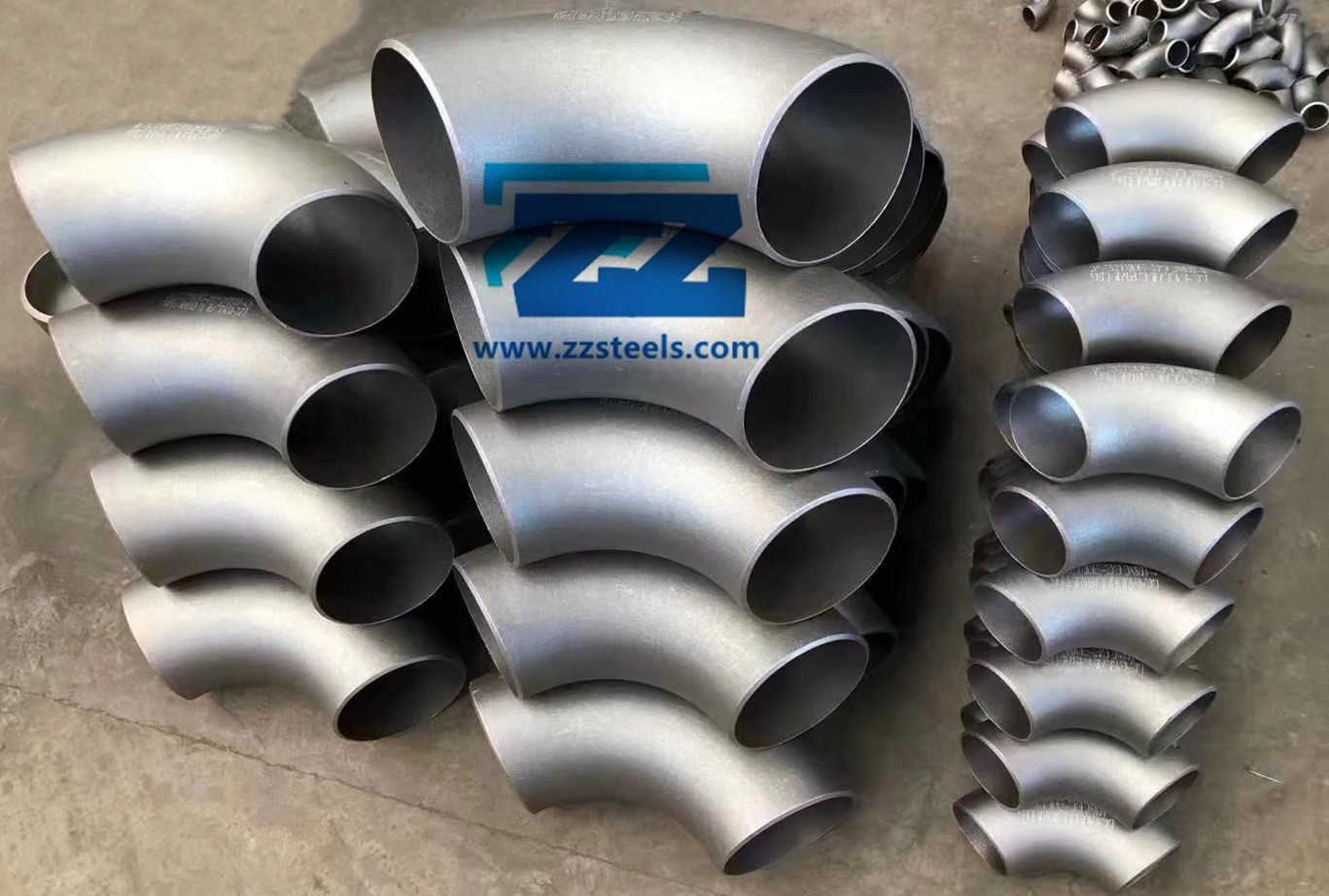

Buttweld Elbow

Butt weld elbows are designed to change the direction of pipeline in a certain degree, such as 90°, 45°, 180° or some special degree such as 60°. Their radius are available in short radius (SR), long radius (LR), 3D, 5D, 10D…… Generally speaking, only 90° elbow and 180° elbow has short radius pattern. Some clients also call the elbows with larger radius than LR as bend. Pipe bend only has butt weld type.

Key elements for ordering stainless steel buttweld fittings elbow: Type, diameter, wall thickness, degree, radius and materials. Eg: 90 Degree BW elbow 14” Sch10S LR ASTM A403 WP316.

BW Tee

Steel pipe tees are used as a branch connection fittings and offers a 90 degree branch to the main pipe. The branch has same size with run pipes (Equal Tee) or has smaller dimensions than the main pipe (Reducing Tee).

The key elements for ordering buttweld tees are type, diameter, wall thickness and material. Eg: BW Reducing Tee DN800 XDN700 Sch 20 SS400.

Stainless Steel Pipe Reducer

Steel Pipe Reducer are only available in butt weld end type. It is used to connect different sizeds pipes and adjust the flow. It can be divided into concentric reducer and eccentric reducer.

How to order a stainless steel pipe reducer? The elements are the same as buttweld pipe tees. Eg: Concentric Reducer 4”x3” Sch 120 A403 WP304.

Buttweld Pipe Cap

Stainless Steel Buttweld Fittings pipe cap is welded to the pipe end to close the pipeline. As a butt weld fitting, it has seamless and welded type. Seamless pipe cap is more common and welded pipe cap usually has large diameters.

The description of butt weld pipe cap is Cap 8″ Sch 40 SMLS ASTM A403 WP310.

Stub End

Stub end also known as lap joint stub end, it is used with lap joint flanges to replace welded flanges. We supply type A stub end, type B stub end and type C stub end for customers. We also offer short pattern and long pattern stub end. The dimension range of stub end is 1/2” to 24”.

Size, schedule, type, length and material are necessary for ordering a butt weld stub end.

Advantages for Stainless Steel Buttweld Fittings

- Excellent corrosion resistance

- Great mechanical properties

- Good weld-ability

- Great leak proof

Stainless Steel Buttweld Fittings Manufacturing Process

The general process include:

Cutting—Heat—Forming—Heat Treatment—Beveled

For seamless buttweld pipe fittings, they are made by cold drawn or hot forming, and welded buttweld fittings usually adopt seam welding to get their shape.

Questions for Stainless Steel Buttweld Fittings

What’s the dimensions for buttweld fittings?

Zizi offers NPS 1/2″ to NPS 80″ ( or DN15 to DN2000 ) stainless steel buttweld fittings.

What does schedule mean for pipe fittings?

Schedule, usually shortened as sch, is an American standard that refers to wall thickness of a pipe or buttweld pipe fitting. ASME standard defines the wall thickness as sch 10s, sch 20, STD, sch 40, XS, sch 80, sch 100, sch120, sch 140, Sch 160 and XXS. The schedule is higher the wall is thicker.

What’s the material grades for stainless steel buttweld fittings?

The most commonly used material grades are ASTM A403 WP304, WP304L, WP316, WP316L, WP310, WP321.

Difference between manufacturer and supplier?

Manufacturer owns machines, presses and equipment to actually make fittings from pipe or plate

Suppliers are intermediaries between manufacturers and end-users.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....