Alloy Steel Forged Fittings Manufacturers

Zizi Engineering is Forged Pipe Fittings producer and exporter that known for competitive price and fast delivery at your doorstep. Recently customer demand large A182 F22 Forged Couplings with NPT Thread, and we provide a vast range of dimension from stock to suit their needs.

But there is a question arises in my mind, why are they so popular?

Threaded Coupling A182 F22

A182 F22 Forged Coupling that we offered are more suitable for industries working at a lower pressure. They are irreplaceable in piping connection.

They are commonly in class 3000 for oil, gas and water pipeline usage. But sometimes they are required in higher pressure application that Alloy Steel F22 Class 6000 Fittings will be shown in the stage.

The standard of Alloy Steel Gr. F22 Forged Fittings is ASME B16.11 which including Socket weld 45 Deg Elbow, Alloy Steel F22 Socket Weld Half Coupling, Alloy Tee, Threaded 90 Degree Elbow, Threaded Bushing, Hex Nipple, Alloy Steel Socket Weld Cap, ASTM A182 GR F22 Union.

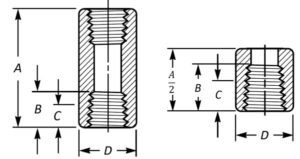

NPT Coupling Dimensions

Zizi engineering fabricates Alloy Steel A182 F22 Forged Fittings according to ASME B16.11. And our A182 F22 Forged Couplings are in active demand.

There are two types of Pipe Coupling which are Full Coupling and Half Coupling. They are different in the thread and the end-to-end length. From their name, we can know the length of full Coupling is twice of half coupling. People frequently used NPT Half Coupling in hose connection as well.

| Nominal

Size |

End to End |

Outside

Diameter |

Thread

Length |

|||

|---|---|---|---|---|---|---|

| A | D | |||||

| DN | NPS | 3000 6000 |

3000 | 6000 | C min |

B min |

| 6 | 1/8 | 32 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 35 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 38 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 48 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 51 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 60 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1 1/4 | 67 | 57 | 64 | 17.0 | 18.0 |

| 40 | 1 1/2 | 79 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 86 | 76 | 92 | 19.0 | 19.2 |

| 65 | 2 1/2 | 92 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 108 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 121 | 140 | 159 | 27.7 | 33.0 |

ASME B1.20.1 is the NPT Standard.

What is ASME B1.20.1?

ASME/ANSI B1.20.1—Pipe Threads, General Purpose, Inch, covers dimensions and gaging of pipe threads of the following series: NPT, NPSC, NPTR, NPSM, and NPSL.

NPT (National Pipe Thread Tapered) is U.S. standard for tapered threads used to join pipes and fittings. This thread is suitable for connections in nearly every type of service without any thread sealant.

NPT Thread Chart

| Nominal Pipe Size |

Number of Threads Per Inch |

Outside Diameter |

|---|---|---|

| 1/8 | 27 | 0.405 |

| 1/4 | 18 | 0.540 |

| 3/8 | 18 | 0.675 |

| 1/2 | 14 | 0.840 |

| 3/4 | 14 | 1.050 |

| 1 | 11.5 | 1.315 |

| 1 1/4 | 11.5 | 1.660 |

| 1 1/2 | 11.5 | 1.900 |

| 2 | 11.5 | 2.375 |

| 2 1/2 | 8 | 2.875 |

| 3 | 8 | 3.500 |

| 3 1/2 | 8 | 4.000 |

| 4 | 8 | 4.500 |

Left-hand threads, add “LH” to the designation. For example: 1⁄2–14 NPT–LH.

QA/QC person will take go-no go gauge test and count the thread number per inch while inspecting A182 F22 Forged Coupling, and each results will be recorded.

Alloy Steel ASTM A182 F22 Forged Fittings

Stainless Steel 316 Coupling is very common for the reason of corrosion resistance and long service life, but Alloy A182 F22 Forged Coupling are not inferior to stainless steel fittings.

ASTM A182 F22 is an Alloy steel contained Chrome and Moly that have great resistance to chloride ion stress corrosion and oxidizing corrosion. They are also have high stress-rupture effectiveness and low creep rates under high stresses after suitable heat treatment. The melting point of is 1510 °C or 2750 °F.

A182 F22 Chemical Composition %

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.05-0.15 | 0.50 | 0.30-0.60 | 0.04 | 0.04 | 0.8-1.25 | 0.044-0.64 |

A182 F22 Mechanical Properties

| Tensile Strength |

Yield Strength |

Reduction of Area |

Elongation |

|---|---|---|---|

| 415-515 Mpa | 205-310 Mpa | 35% | 20% |

Now we get the answer:

- Extensive and irreplaceable application in pipe system.

- Good corrosion resistance and high temperature resistance.

- Excellent mechanical properties.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....