Weld neck flange RF is the most commonly used flange type which has safety and leak-proof connection. It is largely used in various industrial pipe system such as oil and gas, chemical, paper processing, power generation and sea water equipment.

Zizi is manufacturer of ASME B16.5 forged steel pipe fittings and offers Weld Neck Flange RF in different dimensions.

What is a Weld Neck Flange?

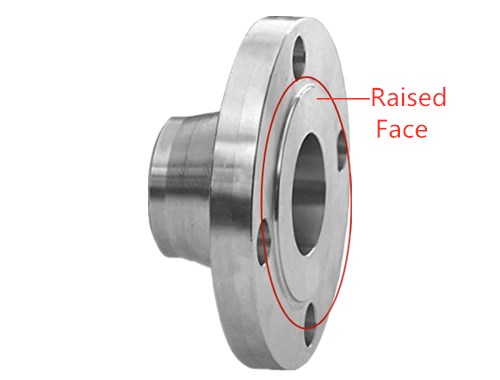

It is very easy to identify a weld neck flange from the appearance because it has a high, tapered hub like a neck. This neck will be welded with pipe so it has the same wall thickness as pipes. It also has the effect of dispersing pressure, making the pipe less deformable.

There are two designs for weld neck flange RF: a regular types we often used with pipes, the other is long hub type which is suitable for process plant.

Raised Face Weld Neck Flange resistant to extreme temperature,high pressure and withstand hostile environments. It is also a ideal choice when the media in pipeline is expensive, flammable or explosive.

What is Raised Face Flange?

Raised face is one kind of seal type of flanges, it means the gasket surface is higher than bolting circle face. This seal face is the most common used one not only among weld neck flanges. What’s more, the height of raised face is changing based on the diameter of flanges. By the way, the seal face is on the opposite of the hub side.

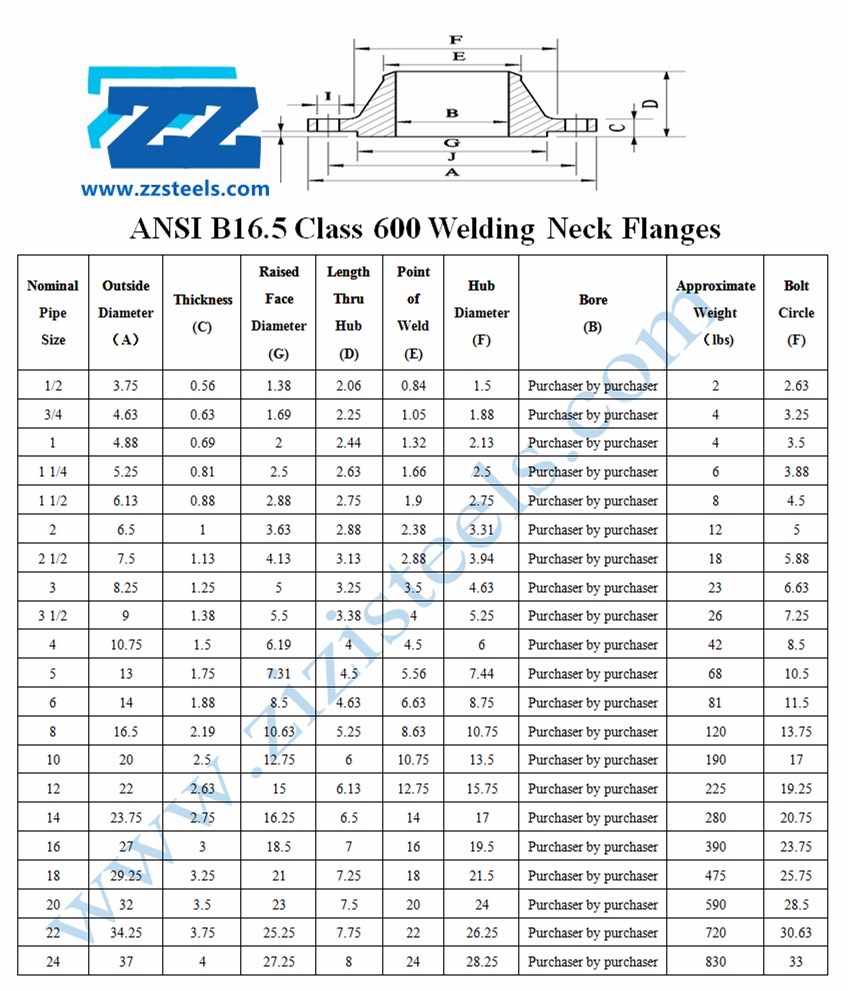

Weld Neck Flange B16.5 Dimensions

Diameter: 1/2 to 24”

Pressure: Class 150, 300, 600, 900, 1500, 2500

Seal: RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint)

Schedule for Seal: Depends on wall thickness of pipes.

Stainless Steel Raised Face Weld Neck Flange

ASTM A182 F304/304L, F306/316L, F309, F31, F317, F321, F347,F454L, ASTM A312/A403 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel Raised Face Weld Neck Flange

ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Steel Raised Face Weld Neck Flange

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM / ASME A 691, ASTM A 106 GR. A, B & C. API 5L GR. B, X 42, X 46, X 52, X 60, X 65

Alloy Steel Raised Face Weld Neck Flange

ASTM / ASME A 182, ASTM / ASME A 335 F1, F5, F9, F11, F12, F22, F23, F91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Copper Alloy Steel Raised Face Weld Neck Flange

ASTM / ASME SB 111 UNS NO. C10100 , C10200 , C10300 , C10800 , C12000, C12200, C70600 C71500, ASTM / ASME SB 466 UNS NO. C70600 , C71500

Nickel Alloy Raised Face Weld Neck Flange

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, NICKEL 200, NICKEL 201, MONEL 400 , ALLOY 20 / 20 CB 3, INCONEL825, INCONEL 600, INCONEL 601, INCONEL 625, HASTELLOY C 276

Quality Control

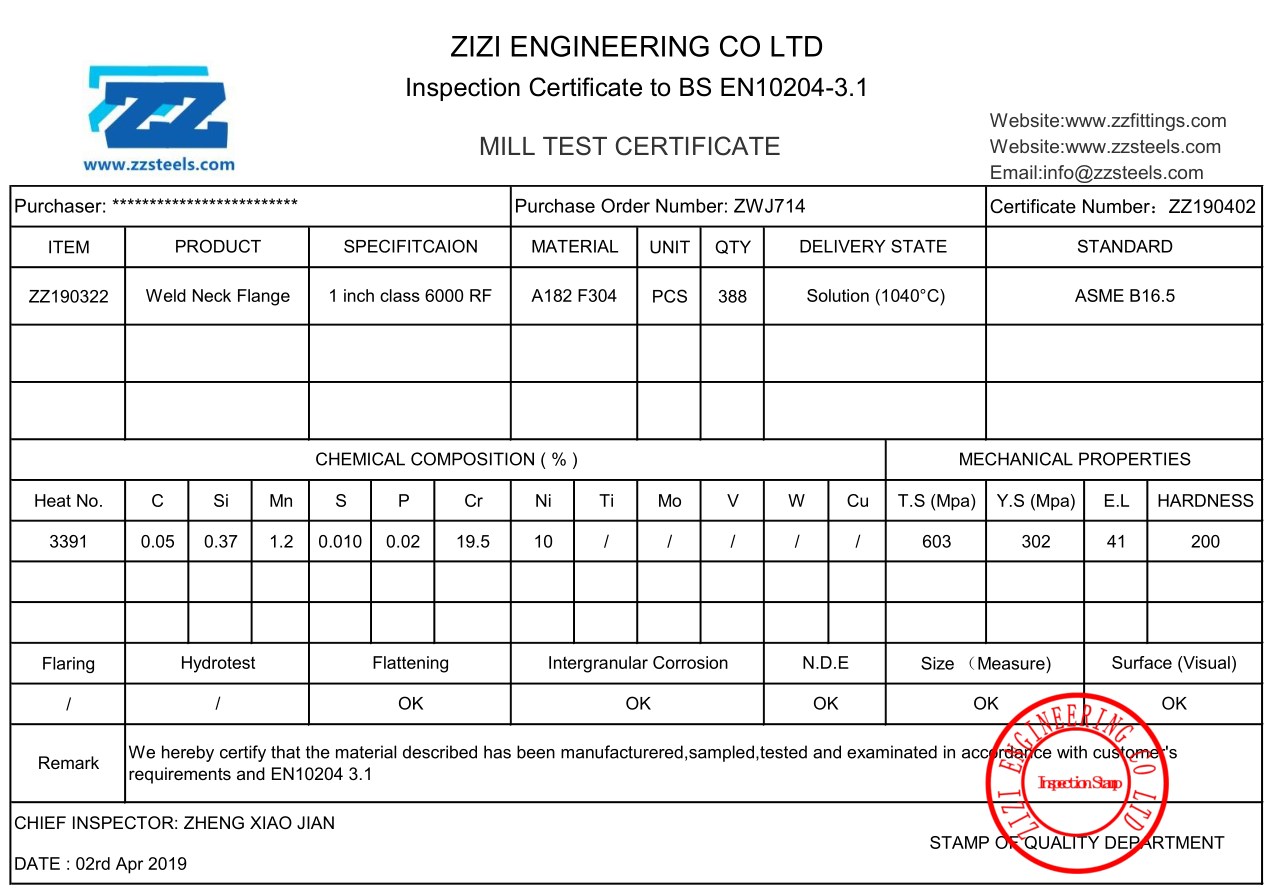

As ISO certified company, we pay a great attentive on the quality. We take a standard inspection to guarantee the quality.

- Marking

- Surface

- Dimension

- Material (MTC)

Tack DN25 Class 600 ASTM A182 F304 Weld Neck Flange RF as an example.

- The marking should correct, clear and beautiful, such as “DN25 600# Weld Neck RF SS304 B16.5 831”.

- Hand touch and visual check to ensure the surface is even and smooth.

- Measure the outside diameter, thickness, raised face diameter and other values according to the dimension chart and compare those value with torelance.

- To prove the quality of material, we will offer you MTC (Mill Test Certificate) for every time.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....