Pipe Flange Sealing Surface Definition

According to the working conditions, media, pressure, specifications, temperature, there are some pipe flange sealing surface types for choice.

- Flat Face (FF)

- Raised Face (RF)

- Female Face (FMF)

- Male Face ( MF)

- Tongue Face (T)

- Groove Face (G)

- Ring Joint Face (RTJ)

Flange Flat Face

This pipe flange sealing surface is flat, applicable to the low pressure, the media non-toxic occasions

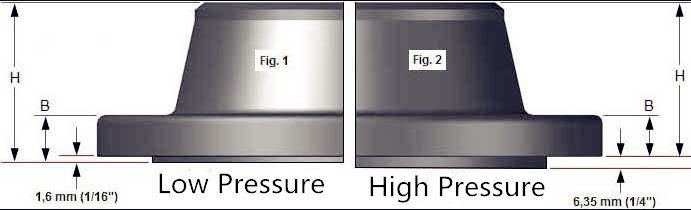

Flange Raised Face

Pipe Flange raised face sealing surface is the most common and practical sealing type. The height is changeless in International standards, European and domestic standards. But it is different with United States standard. The height will be increased with the pressure improves. There are many types of gasket. The gasket suitable for Raised Face Pipe Flanges are below.

- Non-metallic flat gasket

- Clad gasket

- Metal cushion

- Spiral wound gasket

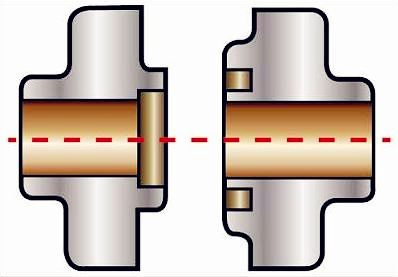

Flange Female and Male Face

Flange Female and Male Face are a pair of sealing surface, and must be compatible with the use, according to the convenience of the installing, but also to prevent the gasket from being squeezed out. Suitable for high pressure occasions.

Concave and convex surface sealing surface applicable to the sealing gasket are below.

- Non-metallic flat cushion

- Coated cushion

- Metal cushion

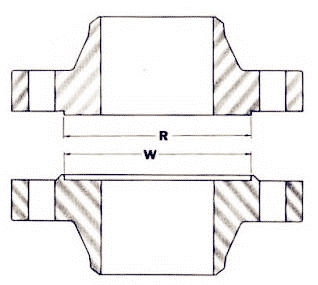

Flange Tongue and Groove Face

Tongue Face and Groove Face is paired to be used. Similar to the emale and male sealing surface.

Both sides of the gasket have a metal wall to restrict the gasket. It will press the gasket in the annular groove into the pipe. So the gasket can avoid pressure deformation.It is less affected by the corrosion of the fluid medium, because the gasket is not directly contact with the medium. So, it is suitable for high pressure, inflammable and explosive, poisonous medium and so on. But the sealing surface processing is more difficult, and the gasket replacement is easy to damage the seal surface. So the installment and the disassembly must be in the axial separation. The possibility of axial separation should be noted when design.

Tenon Groove sealing surface are in below application

- Metal and non-metallic flat cushion

- Metal cushion

- Spiral wound gasket

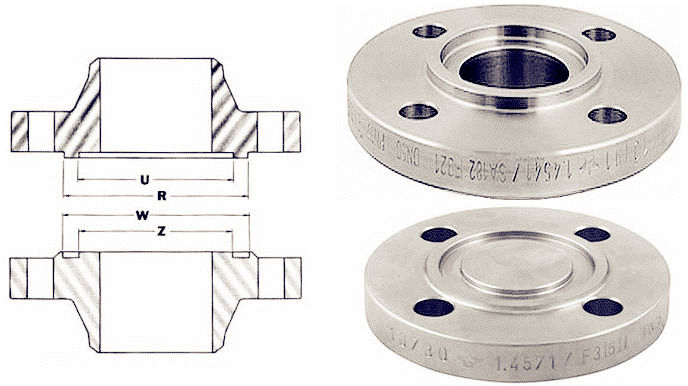

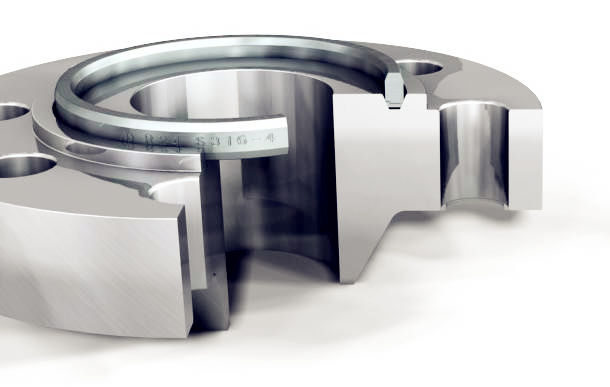

Ring Joint Face of Flange

Ring joint face belongs to the narrow flange as well. It has a annular trapezoidal groove on the face as the flange sealing surface. Like the tenon groove flange, this sealing face must be separated from the flange in the axial direction when installation and disassembly.

This specially designed sealing surface can be used with metal materials to form octagonal or oval-shaped solid metallic gaskets for sealed connection. The metal ring gasket can have different properties based on the inherent characteristics of various metals. Therefore, the sealing performance is good, and installation requirements are not too strict. It fits for high-temperature, high-pressure conditions, but the sealing surface processing accuracy is higher.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....