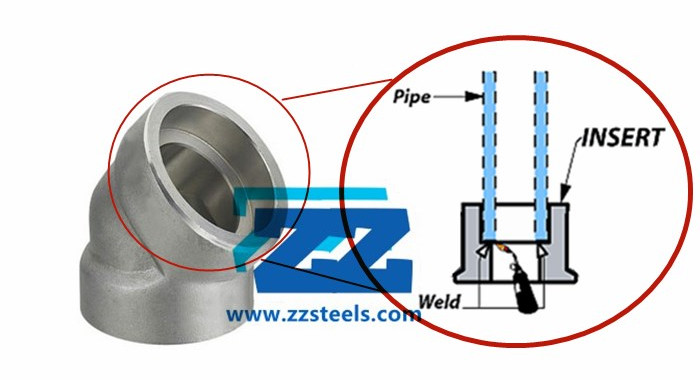

Socket weld elbow is forged steel pipe fittings that used to provide direction changes in different degrees. 90° and 45° elbow is the most prevalent type. It is also an important and useful part for same or different sizes pipe connection. Socket welding is the connection way, that is insert pipes into a trapezoidal area of the elbow ends, then weld them together.

Features of Forged Steel Elbow

Socket weld fittings are fabricate by forging and pressing,

- Less defect

- Fine microstructure

- Great mechanical properties

- Withstand to high load working environment

Advantages of Socket Weld Fittings

- Withstand to high pressure

- Leak-proof

- Easy to align and weld

- No need to prepare for welding

How to Order Socket Weld Ebow

- Degree

Steel pipe elbows are available in many degrees such as 90°, 45°, 180° and other special degrees according customer’s require, but the standard socket weld elbow is only 90° elbow and 45° elbow.

- Diameter of two end

The diameter is form 1/8” to 4”. Based on the sizes of two end, there are equal / straight elbow and reducing elbow.

Equal elbow / straight elbow is the diameter of two ends is the same.

Reducing elbow has different diameters at two ends (one end is larger and the other end is smaller).

- Pressure

Pressure refers to the wall thickness of forged fittings. Socket weld elbow is available in class 3000, 6000 and 9000.

- Standard

ASME standard is very popular overseas, and ASME B16.11 is served for forged steel pipe fittings. But there are many other standards are available such as BS 3799 and JIS b2316.

According to ASME B16.11, socket weld pipe fittings should be used with inch pipes, while some standard not specified Metric tube or inch pipe it will be use.

As we all know, radius is also important feature for pipe elbows, but forged elbow is not classified by this element.

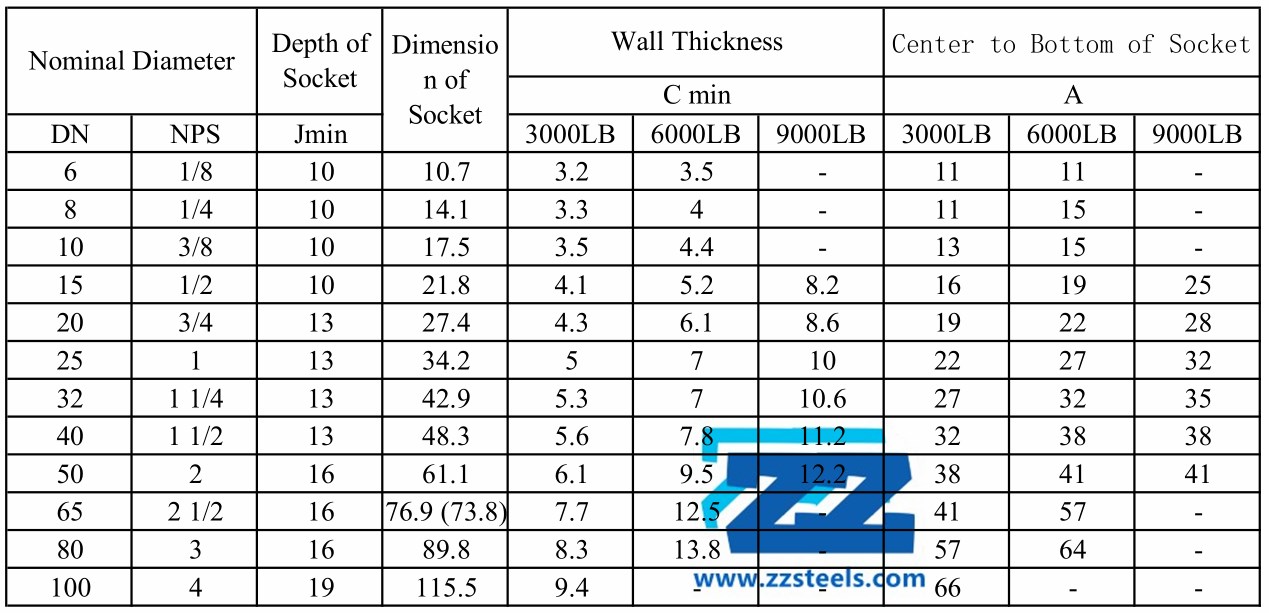

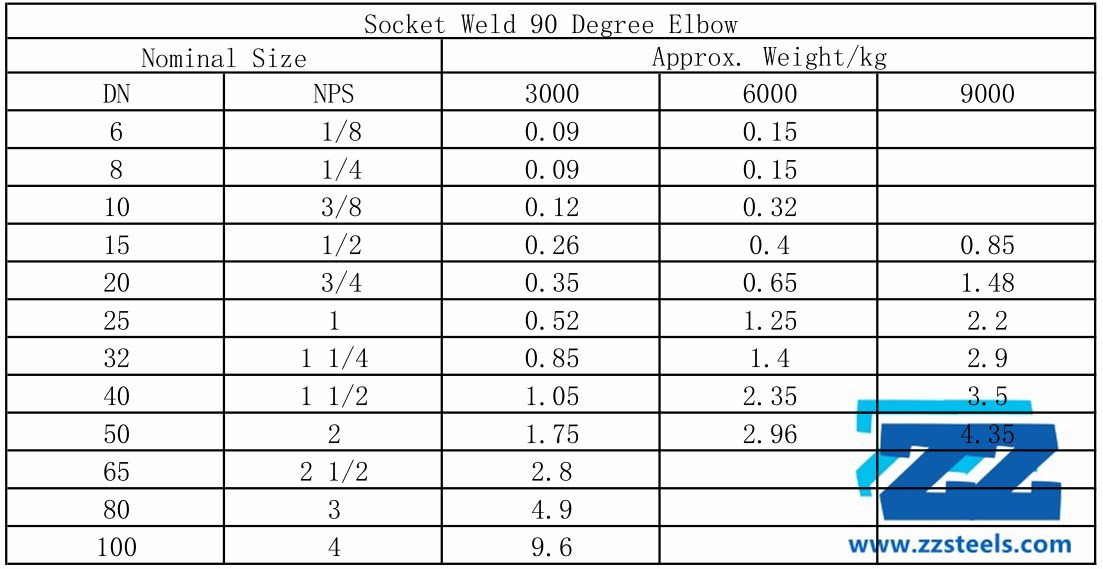

Socket Weld Elbow Dimensions & Weight

90 Degree Elbow Dimensions

90 Degree Elbow Weight

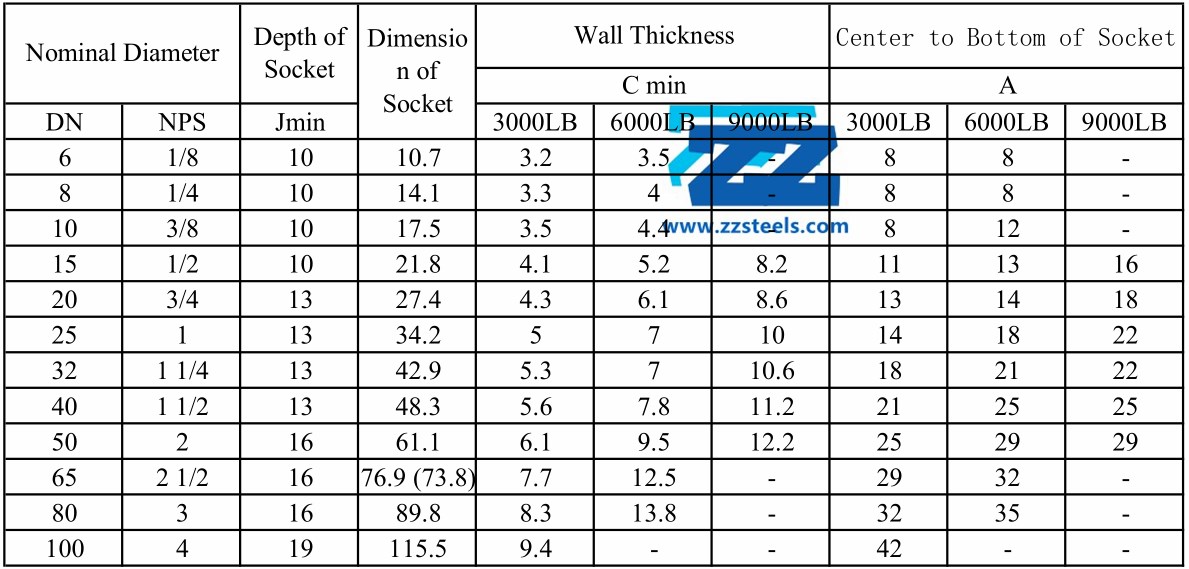

45 Degree Elbow Dimensions

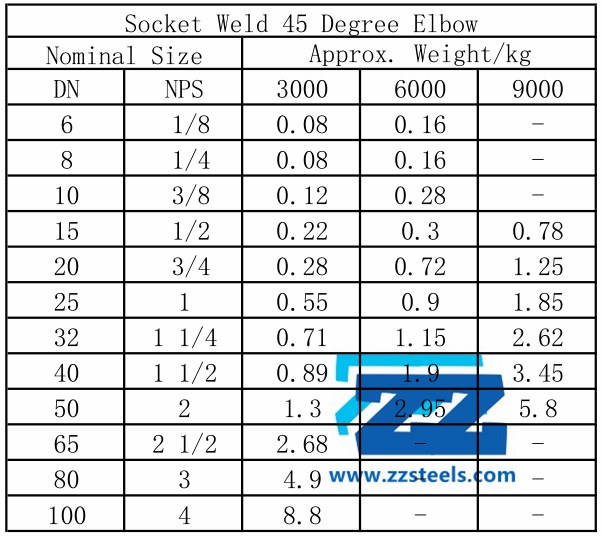

45 Degree Elbow Weight

Materials for Forged Steel Pipe Fittings

Carbon steel Socket Weld Elbow

ASME A105, A350 LF/LF3, A106 A/B/C, API 5L

Stainless Steel Socket Weld Elbow

ASTM A182 F304, F316, F310, F321, F309, F317

Duplex Stainless Steel Socket Weld Elbow

ASTM A182 F51, F53, F55 / UNS S31803, S32205, S32550, S32750, S32950

Alloy Steel Forged Steel Elbow

ASTM A182 F1, F5, F9, F11, F12, F22, F91

Nickel Alloy Forged Steel Elbow

UNS2200 (NICKEL 200) , UNS2201 (NICKEL 201 ) , UNS4400 (MONEL 400 ), UNS8825 (INCONEL 825) , UNS6600 (INCONEL 600 ) , UNS6601 (INCONEL 601) , UNS6625 (INCONEL 625) , UNS10276 (HASTELLOY C 276)

Copper Alloy Forged Steel Elbow

UNS NO. C 70600 ( CU -NI- 45/10) , C 71500 ( CU -NI- 70/30), C70600 C71500

Application

High pressure and precision requirements applications such as

- Oil and gas

- Chemical

- Power Generation

- Aerospace

- Metallurgy

- Shipbuilding

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....