Spectacle Blind Class 900 DN500

What is a Spectacle Blind Used For?

High quality forged flanges supplier Zizi offers DN500 Class 900 spectacle blind RF ASTM A182 F91 for Australia, those flanges are manufactured according to ASME B16.5.

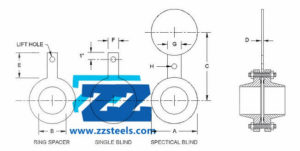

Spectacle blind is very useful where the pipe need regularly separated or maintained. It consist a solid disc and a ring, they are attached by a small section of steel. You can place the solid disc or the ring between two pipes to block off the pipe or keep the flow smooth.

Zizi produces steel pipe fittings and flanges in various dimensions and materials for customers, and we will cater you requirements no matter of quality or of service.

Dimensions of Spectacle Blind Class 900

Size: DN500/ NPS20 900LB Spectacle Blind

Outside Dia. A: 27.38

Bore Dia. B: 19.56

Blind Distance C: 29.5

Plate Thickness D: 2.88

Handle Width G:5.25

Lift Hole Dia. H: 2.1

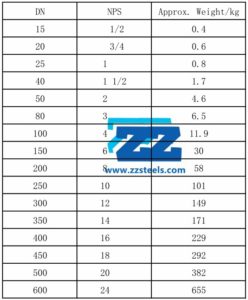

Spectacle Blind Class 900 Weight

Package of Spectacle Blind Raised Face

For the large diameter 900LB spectacle blind, we will use

- Anti rust oil

- Plastic Film

- Wooden Cases

ASME B16.5 Forged Flanges Dimensions

| Standard | ASME B16.5, API 5A |

|---|---|

| Diameter Range | 1/2 to 24 inch / DN15-DN600 |

| Pressure Rate | Class 150, 300, 600, 900 Spectacle Blind, 1500, 2500 |

| Stainless Steel | ASTM A182 F316, F316L, Gr304/304L, SS317, SS321, SS310 |

| Duplex Steel | ASTM A182 F51, F53, F55 |

| Carbon Steel | ASTM A105N, A350 LF2/LF3. A694 F60, F65, F70, F52 |

| Alloy Steel 900# Spectacle Blind | ASTM A182 F1, F5, F9, F11, F12, F22 ,F91 |

Flange Types

- Weld Neck Flange

- Slip On Flange

- Threaded Flange

- Socket Weld Flange

- Blind Flange

- Lap Joint Flange

- Spectacle Blind

Spectacle Blind Application

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Off-Shore Oil Drilling Companies

- Power Generation

- Gas Processing

Why Choose Us

- Reasonable Price

- Best Quality

- Fast Delivery

- On Step Service

ASTM A182 F91 Properties

Chemical Composition, %

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.08-0.12 | 0.3-0.6 | 0.02 | 0.01 | 0.2-0.5 | 0.4 | 8-9.5 | 0.85-1.05 |

Mechanical Propperties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 585 | 415 | 20 |

此站点遇到了致命错误。