Type A Stub End Short Pattern

Type A Stub End

Type A stub end is used with lap joint flanges. It is a buttweld fittings which is available in 1/2” to 24” according to ASME B16.9.

Lap joint stub end mainly has two pattern: short pattern and long pattern. Short pattern also called MSS-A stub end, and long type called ASA-A stub end or ANSI length stub end. The main difference between them is their length.

Zizi is high quality buttweld fittings supplier and we have sufficient inventory of stub end both in long pattern and short pattern.

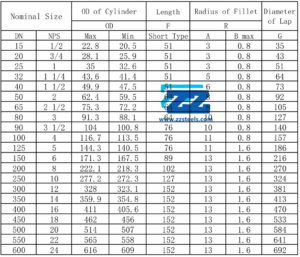

Stub End Short Pattern Dimensions

| Standard | ASME B16.9, MSS SP-43, JIS B2312 |

|---|---|

| Diameter | NPS 1/2” to 24”, DN15 to DN600 |

| Wall Thickness | Schedule 10S, 20, STD, 40, XS, 80, 120, 160, XXS |

| Type | Seamless, Welded Type A Stub End Short Type |

| End | Plain, Beveled, Flanged, Grooved |

Materials for ASME B16.9 Buttweld Fittings

Stainless Steel Stub End Short Pattern

ASTM A403 WP304/304L/304H, WP316/316L, WP 309, WP310, WP317, WP321, WP347

Carbon Steel Stub End Short Pattern

ASTM A234 WPB, A860 WPHY42, WHPY52, WPHY60, WHPY65, WPHY70, A420 WPL 3 / 6 / 9.

Alloy Steel Stub End Short Pattern

ASTM A234 WP1, WP5, WP9, WP11, WP12, WP22, WP91

Duplex Stainless Steel Stub End Short Pattern

ASTM A815 UNS S 31803, 32205, 32550, 32750, 32760

Order of Stub End Short Pattern Type A

Item: Type A Stub end short pattern

Size: 10” Sch 20

End: Beveled

Type: Seamless

Material: ASMT A234 WP11

Standard: ASME B16.9

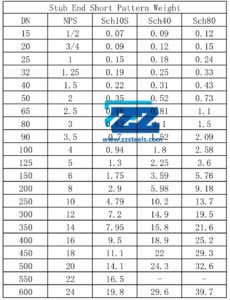

Stub End Weight

Inspection of Buttweld Fittings

The inspection is operated according to ASME B16.9

Check the surface

- Marking includes size, material, standard and Lot No. Be sure they are correct and clear.

- Touch and visual check the surface to ensure it is smooth and even.

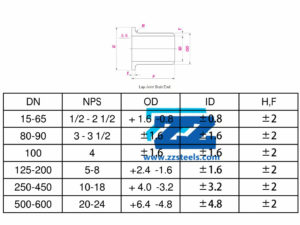

Measure the size

- Measure diameter, length, radius.

- Confirm the sizes are in tolerance.

Approve third party inspection

- Third parties such as BV, SGS, LR, DNV, ABS.

- Offer stamped Mill Test Certificate.

Advantages of Lap Joint Stub End

There are two main advantages for using stub end with flanges:

- Reduce the total cost.

With using stub end, the material of lap joint flange can be lower grades than pipe lines. For example, in a stainless steel pipe line, you can use a stainless steel stub end and a carbon steel lap joint flange instead of using a full stainless steel weld neck flange to saving the cost.

2. Speeds up the installation process.

Type A stub end can help simplify and align the bolt holes of flanges. The usage of stub end is becoming prevalent both in low pressure applications and high pressure applications.

Why Choose Us Steel Pipe Fittings

- ISO Certified Quality

- Attractive Price

- Fast Delivery

- One Step Service

A234 WP11 Material

Chemical Composition,%

| C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.05-0.2 | 0.3-0.8 | 0.03 | 0.03 | 0.5-1 | 1-1.5 | 0.04-0.65 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 415-585 MPa | 205 MPa | 20 % |

此站点遇到了致命错误。