What is Flange?

Forged industrial flange dimensions cover steel material, size, seal face, pressure rating, schedule, standard and flange types.

Flange is one of the most common parts in engineering design. It is a piping design, pipe valve essential parts, but also necessary components for equipment and equipment components (such as manhole, mirror liquid level meter, etc.). In addition, other professions also often use flange joints,such as industrial furnaces, thermal technical, water supply and drainage, heating and ventilation, self-control, etc.

Forged Steel Flange Material

Forged Steel, WCB Carbon Steel, Stainless Steel, 316L, 316, 304L, 304, 321, CR-MO Steel, CR-mo Vanadium Steel, Molybdenum Titanium, Liner, Fluorine-lined Material.

Standard of Pipe Flange

GB, JB, HG, ASME B16.5, BS4504, DIN, JIS

Flange Type

PL Flange,Slip On Flange,Weld Neck Flange, Lap Joint Flange,Socket Weld Flange,Blind Flange and so on.

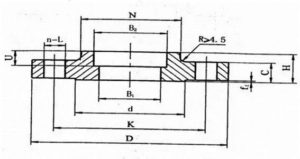

PL Flange Dimensions

PL Flange

Advantages:Convenient, manufacture simple, low cost, widely use

Shortcomings: Poor rigidity is poor, not suitable for the chemical process piping system, extremely hazardous occasions which have supply and demand, flammable, explosive and higher vacuum requirements

The sealing type: Flat Face and Raised Face

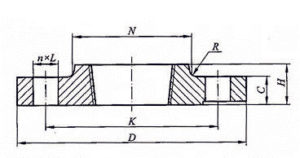

Slip On Flange Specification

Slip On Flange

Advantages:Easy to install on site and omit the process of rubbing the weld

Shortcomings: The height of Slip On Flange neck is lower, the stiffness and bearing capacity of the flange are higher. Compared with the Weld Neck Flange, the welding workload is large and electrode consumption is high, also can not withstand high temperature,high pressure,repeated bending and temperature fluctuation.

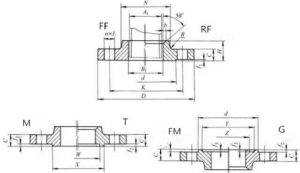

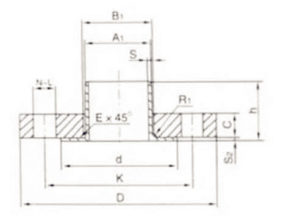

Weld Neck Flange Dimensions

Weld Neck Flange

The sealing type: RF,FM,M,T,G,FF

Advantages:The connection is not easy to deform, seal is good and application is widespread. It is applies in the temperature or the pressure large fluctuation pipeline or the high temperature, the high pressure and the low temperature pipeline, also uses in the transporting expensive medium, flammable explosive medium and poisonous gas pipeline

Shortcomings:Large size, heavy weight, expensive, installation positioning is very difficult. Also easy to bump in transit.

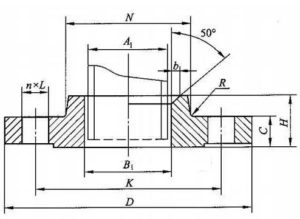

Integral Flange Specification

Integral Flange

The Integral Flange is a flange connect method. Also belongs to weld neck flange. Material has carbon steel, stainless steel, alloy steel and so on. In China standards,”IF” means Integral Flange.

Mostly used in higher pressure pipeline. The manufacture process is generally cast.

In the flange type, an “IF” is the type of integral flange.

Generally it is raised face (RF), if in the flammable, explosive, high and extreme hazards of working conditions, you can choose MFM and TG sealing type.

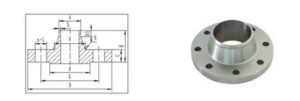

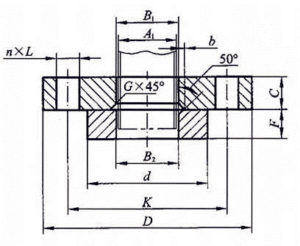

Socket Weld Flange Dimensions

SW Flange drawing

Socket Weld Flange

Socket Weld Flange is one end weld on pipe and the other connect by bolts.

The sealing type: RF,MFM,TG,RJ

Application: Boiler Pressure Vessels, Petroleum, Chemical, Shipbuilding, Pharmaceutical, Metallurgy, Machinery, Stamping Elbow Food and other industries.

Used in the pipeline which PN≤10.0MPa,DN≤40

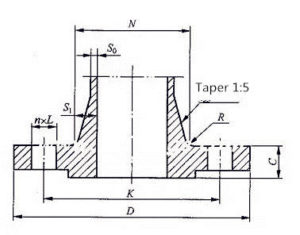

Threaded Flange Specification

Drawing of Thread Flange

Thread Flange

The thread flange is a kind of non welded flange which is machined flange inner hole into thread, and connected with the thread end.of pipe.

Advantages:Compared with Slip On Flange and Weld Neck Flange, the thread flange has the features of easy installation, maintenance, can be used on some sites that not allow welding pipeline. Alloy Steel Flange has enough strength, but difficult to weld, or welding performance is not good,also can choose thread flange.

Shortcomings:Under the condition that pipeline temperature is changed sharply or higher than 260 ℃ and below-45 ℃, to avoid leakage, the threaded flange is not recommended.

Butt Weld Ring Loose Flange Dimensions

Butt Weld Ring Loose Flange

The Butt Weld Ring Loose Flange is movable.Generally supporting in the water supply and drainage fittings, each end of the expansion joint has a flange while sending. Connecting the pipe and equipment by bolts directly in the project.

The purpose of using is to save the material. it is divided into two parts, the pipe part is connected with the pipe, and the other end is made into butt weld ring. The ring flange is made by low grade material, but the pipe part uses the same material as the pipeline.

Advantages

Cost savings. When the material of pipe is special and expensive, the same material of flange is costly.

Not easy to weld or inconvenient to process or require a large strength. such as plastic pipes, glass pipes and so on.

Convenient for construction. While in connection, the flange bolt hole corresponding is not easy to find positive or prevent future replacement equipment, flange bolt hole has changed.

Shortcomings

Withstand low pressure

Low strength at weld ring (especially when thickness is below 3mm)

Flat Weld Ring Loose Flange Specification

PJPR Flange

Flat Weld Ring Loose Flange is movable. Connect with the pipeline and equipment by bolts directly in the project.

The purpose of using is to save cost, it is divided into two parts, the pipe part is connected with the pipe, and the other end is made into stub, and the flange plate is set on the stub.

The flange plate uses the low grade material, but the pipe part uses the same material as the pipeline, achieves the saving purpuse.

Advantages:

Cost savings. When the material of pipe is special and expensive, the same material of flange is costly.

Not easy to weld or inconvenient to process or require a large strength. such as plastic pipes, glass pipes and so on.

Convenient for construction. While in connection, the flange bolt hole corresponding is not easy to find positive or prevent future replacement equipment, flange bolt hole has changed.

Shortcomings

Withstand low pressure

Low strength at weld ring (especially when thickness is below 3mm)

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....