Lap Joint Flange Stub End

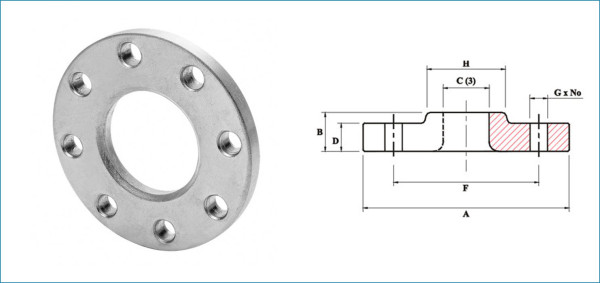

Sometimes we call Lap Joint Flange as Loose Flange which used in conjunction with a “Lap Joint Stub End”. Their dimension is same as other flanges.

They are widely used in Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, and Pipe Projects.

Flange Specification

- Material:Carbon steel: A105,SS400,SF440 RST37.2,S235JRG2,P250GH,C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti

- Standard:ANSI,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820

- Size:1/2-78 inch (DN15-DN2000)

- Pressure:ANSI class 150,300,600,1500,2500, DIN PN6, PN10, PN16, PN25, PN40, PN64,PN100,PN160

- Packing:No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment:Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

Loose Flange Advantage

- Freedom to swivel around the pipe facilitates the lining up of opposing flange bolt holes.

- Lack of contact with the fluid in the pipe often permits the use of inexpensive carbon steel flanges with corrosion resistant pipe.

- In systems which erode or corrode quickly, the flanges may be salvaged for re-use.

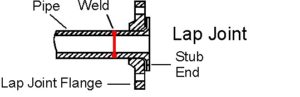

Connection of Lap Joint Flange

How to connect? Let us introduce to you. It connects to pipe by welding as well. It is the stub end welded to the pipe and the flange is sleeved and clamped to it. Then seal the stub end and gasket by bolting two flanges.

What is Stub End?

Stub End is a type of steel butt welded pipe. It is a short piece of pipe with a narrow shoulder on the end. The other end is butt welded to a pipe, this end called hub. The shoulder is like a raised face of flange, the hub is a neck.

It has long and short types. ASME B16.9 Stub Ends have both long and short pattern, but MSS SP-43 Stub End is available in short pattern only.

Stub End Dimensions

| Nominal pipe size | Lap diameter | Outside diameter | Long pattern length | Short pattern length | Radius |

|---|---|---|---|---|---|

| Inch. | A/mm | OD/mm | L/mm | L/mm | R/mm |

| 1/2 | 35 | 20.5-22.8 | 76 | 51 | 3 |

| 3/4 | 43 | 25.9-28.1 | 76 | 51 | 3 |

| 1 | 51 | 32.6-35 | 102 | 51 | 3 |

| 1 1/4 | 64 | 41.4-43.6 | 102 | 51 | 5 |

| 1 1/2 | 73 | 47.5-49.9 | 102 | 51 | 5 |

| 2 | 92 | 59.5-62.4 | 152 | 64 | 8 |

| 2 1/2 | 105 | 72.2-75.3 | 152 | 64 | 8 |

| 3 | 127 | 88.1-91.3 | 152 | 64 | 10 |

| 3 1/2 | 140 | 100.8-104 | 152 | 76 | 10 |

| 4 | 157 | 113.5-116.7 | 152 | 76 | 11 |

| 5 | 186 | 140.5-144.3 | 203 | 76 | 11 |

| 6 | 216 | 167.5-171.3 | 203 | 89 | 13 |

| 8 | 270 | 218.3-222.1 | 203 | 102 | 13 |

| 10 | 324 | 272.3-277.2 | 254 | 127 | 13 |

| 12 | 381 | 323.1-328 | 254 | 152 | 13 |

| 14 | 413 | 354.8-359.9 | 305 | 152 | 13 |

| 16 | 470 | 405.6-411 | 305 | 152 | 13 |

| 18 | 533 | 456-462 | 305 | 152 | 13 |

| 20 | 584 | 507-514 | 305 | 152 | 13 |

| 22 | 641 | 558-565 | 305 | 152 | 13 |

| 24 | 692 | 609-616 | 305 | 152 | 13 |

MSS SP-43 Butt Weld Fittings

This standard provides dimensions, tolerances, and markings for wrought and fabricated Butt-Welding Stainless Steel Fittings for low pressure, corrosion resistant conditions. This Standard Practice covers only fittings made for use with Schedule 5S or 10S Pipe, for all NPS sizes listed in ASME B36.19M, except that short pattern stub ends suitable for use with Schedule 40S are also shown.

There are many types for different standard. MSS SP-43 Fittings include 90° & 45° Long Radius Elbows, Equal Tees and Reducer Tees, Long Lap Joint Flange Stub Ends, Pipe Caps, 180° Long Radius Returns, Concentric and Eccentric Reducers.

The standard materials of MSS SP 43 cover austenitic stainless steel Types 304/ 304L, 316/ 316L, 317/ 317L, 321 and 347. The fittings can also be made of nonferrous metals such as titanium Gr.1, Gr.2, Gr.3, Gr.5, Gr.7, Gr.12; Inconel 600, Inconel 625, Hastelloy C-276, Hastelloy C-22, Monel 400, Incoloy 800, Incoloy 825/ 925, Alloy 31, Alloy 20

Industrial Flange Types

Threaded Flange

Sometimes Threaded Flanges are also known as Screwed Flange in some area, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe. This type of joint connection is Speedy and simple but not suitable for high presser and temperature applications. Threaded Flanges are mostly used in utility services such as air and water.

Socket Weld Flange

Same as other socket weld fittings, socket Weld Flanges have a female socket in which pipe is fitted. Fillet welding is done from outside on the pipe. Generally, it is used in small bore piping and only suitable for low pressure and temperature application.

Slip-On Flange

The economical flange type that Slip-On Flanges have a hole with matching outside diameter of pipe from which pipe can pass. The flange is placed on pipe and fillet welded from both inside and outside. Usually suitable for low pressure and temperature application. This type of flange is available in large size also to connect big bore piping with storage tank nozzles. Normally, these flanges are of forged construction and are provided with the hub. Sometimes, these flanges are fabricated from plates and are not provided with the hub.

Lap Joint Flange

People always say it is similar with slip on flange and have components, a stub end, and a loose backing flange. Stub end is butt welded to the pipe and Backing flange freely move over the pipe. The backing flange can be of different material than stub material and normally of the carbon steel to save the cost. Lap flange is used where frequent dismantling is required, and space is constrained.

Weld Neck Flange

While the most common flange is Weld Neck Flange that are widely used flanged in process piping. It gives the highest level of joint integrity due to Butt-welded with a pipe. These types of flanges are used in high pressure and temperature application. Weld neck flanges are Bulky & costly with respect to other types of flange.

Blind Flange

The Blind Flange is a blank disc with bolt hole. These types of flanges are used with another type of flange to isolate the piping system or to terminate the piping as an end. Blind flanges are also used as a manhole cover in the vessel

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....