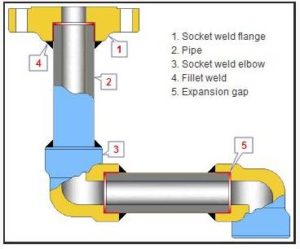

Socket Weld Fitting

Socket welding is a pipe connection method for inserting pipe into valve,fittings and flange. It is usually used for 2-inch or below.

Socket welded joint is a good choice when the high structural strength requirement and high leakage risk become design considerations.

The fatigue strength of the socket weld joint is lower than butt weld joint because of the mutation of the filled weld and the geometrical structure. However, socket welded joint is superior to other mechanical joints.

Socket weld pipe fittings are high pressure which applied in various industrial processes, the features are as below

- Used in transferring flammable medium without leakage, poisonous or expensive medium and 300PSI to 600PSI steam

- It is only connected to the ASME Pipeline with the same diameter.

- Used in piping permanent work and provide better flow characteristics.

- The materials are ASTM, and standards are ASME B16.11 whcih including pressure-temperature ratings, dimensions, tolerances, marking and carbon steel, stainless steel and alloy steel material requirements. It can be forgings, round rods, seamless pipe. Common materials are ASTM A105, A182 or A350

There are three pressure rating. Class 3000, 6000, 9000

|

Type |

Pressure Rating | ||

|---|---|---|---|

|

3000 |

6000 |

9000 |

|

|

45° and 90° Socket Weld Elbow |

1/8–4 |

1/8–2 |

1/2–2 |

|

Socket Weld Tee Cross Coupling |

1/8–4 | 1/8–2 |

1/2–2 |

|

Half Coupling |

1/8–4 |

1/8–2 |

1/2–2 |

|

Cap |

1/8–4 |

1/8–2 |

1/2–2 |

| Pipe Thickness Schedule | Sch80, XS | Sch160 |

XXS |

Forged Socket Weld Fittings

Advantages

- Beveling is not necessary

- Spot welding is not necessary

- The weld material will not penetrate into the pipeline hole.

- Allow to instead threaded pipe fittings, and reduce the risk of leakage.

- The fillet weld is not suitable for radiographic inspection, so proper fitting and welding is critical. Fillet weld usually use magnetic particle and penetrate to do surface detection.

- The cost is lower than butt weld

Socket Welding Fittings

Disadvantages

- Welder shall ensure the welding expansion space between pipe and socket shoulder 1.6mm during welding.

- The existence of cracks in welding gap and socket weld, which reduces the corrosion resistance or radiation resistance of the pipeline. When the solid particles are piled up at the socket weld, the pipeline operation and maintenance may fail. In this case, the entire pipe is usually required to be fully welded butt welds.

- Socket welding does not apply to ultra-high pressure food industry. Because it is not fully welded, leaving overlap and cracks, it is difficult to clean, the formation of false leakage.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....