Stainless Steel Threaded Elbow

SS 316 Threaded Elbow is pretty and easy to use. It is forgings and thread type is BSP and NPT. Usually clients are buying the stainless steel threaded elbow, because it has long life service against rust.

Order of 90 Degree SS 316 Threaded Elbow

Last week a Ghana customer requested the price of 90 degree 1 inch 2000# NPT Threaded Elbow SS 316. We worked out the price at the first time.

The SS 316 Threaded Elbow is Straight, which has equal size of both end. If two end are in different size, it called Reducing Elbow, and its weight will change as well. Another customer ordered 90 Degree Reducing Elbow some weeks ago, and we also provided them elbow photos package picture and certificate after delivered. The package is wood case.

Stainless Steel 90 Degree Threaded Elbow

Stainless steel has advantages of non – toxic, light weight, good heat resistance, corrosion resistance, thermal insulation, anti – punching performance, long service life. So SS 316 Threaded Elbow and Stainless Steel 304 Threaded Elbow is popular. The main difference in chemical composition that Stainless Steel contains Mo and NI, and the former is more resistant to corrosion than the latter at high temperature.

Threaded Elbow Dimensions

The dimension charts of elbow just apply to straight elbow, but what if customer inquiries the price of Reducing Elbow? Let me tell you. We have manufactured DN25x15 Reducing Elbow Threaded SS 316 , and its weight can be calculate based on the Straight Threaded elbow chart.

The degrees are 90 degree and 45 degree.

Pressure is also a factor which influences weight. The pressure rating is 2000#,3000# and 6000#.

| Nominal Diameter | Approximate Weight | |||

|---|---|---|---|---|

| DN | NPS | 2000lb | 3000lb | 6000lb |

| 6 | 1/8 | 0.08 | 0.1 | 0.18 |

| 8 | 1/4 | 0.08 | 0.15 | 0.3 |

| 10 | 3/8 | 0.13 | 0.3 | 0.45 |

| 15 | 1/2 | 0.22 | 0.45 | 0.72 |

| 20 | 3/4 | 0.32 | 0.7 | 1.2 |

| 25 | 1 | 0.5 | 1.21 | 1.65 |

| 32 | 1 1/4 | 0.8 | 1.47 | 2.7 |

| 40 | 1 1/2 | 0.93 | 2.6 | 3.3 |

| 50 | 2 | 1.6 | 3.05 | 6.05 |

| 65 | 2 1/2 | 2.95 | 5.8 | 9.88 |

| 80 | 3 | 5.6 | 8.85 | 16.4 |

| 100 | 4 | 10.5 | 13.5 | 23.5 |

Threaded Fitting Standard

BSP (British Standard Pipe) is a family of technical standards for screw threads. It has been adopted internationally for interconnecting and sealing pipes and fittings by mating an external (male) thread with an internal (female) thread.

Zizi Engineering usually manufactures based on standard ASME B16.11, but we also have some customers from Europe, so BS3799 threaded elbow is the products our customers need as well. The former is American standard, and the latter is British standard

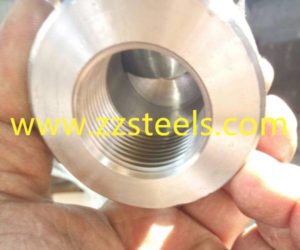

SS 316 Threaded Elow Quality Control

Every fitting is subjected to three separate quality control systems: one for material control, one for manufacturing control, and one for design control.

All threaded elbow fittings are inspected before being passed to shipping room. Frequent analyses are made to check against mill documents. Accurate records are kept of every fitting from initial forging bar through forging, heat treatment, machining, storage and shipment. Every single fitting is traceable to the exact material and process used in its manufacture.

Threaded Elbow Inspection

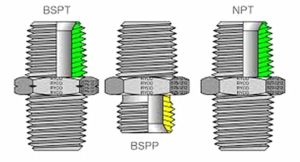

Elbow Thread Type

NPT and BSP is two kinds of thread type. BSP has appurtenant types, so BSPP Threaded Elbow and BSPT Threaded Elbow is BSP Fittings as well. In addition to these, Zizi also manufactures GI threaded elbow, GI means galvanized, it has electroplated and hot dip galvanized two types.

Threaded Type

What is NPT

NPT stands for National Pipe Tapered threads, also known as ANSI/ASME B1.20.1 pipe threads. It is a U.S. standard for measuring tapered threads on threaded pipes and fittings. Unlike straight threads found on a bolt, a taper thread will pull tight, making a closer seal.

What is BSP

BSP (British Standard Pipe) is a family of technical standards for screw threads that has been adopted internationally for interconnecting and sealing pipes and fittings by mating an external (male) thread with an internal (female) thread.

Difference between BSPP and BSPT

BSP, BSPP and BSPT also have differences. For BSPT thread, angle of across the flanks of threads (if you sliced the fitting in half long-ways and measured the angle from root to crest to root) is 55 degrees instead of 60 degrees as it is for NPT. Thus an NPT male will fit into a BSPT fitting or vice versa but they will not seal.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....