What is Pipe Cap

Pipe Caps are including socket weld cap. threaded cap and butt weld cap which has the same function with pipe plug.They are welded or screwed to a pipe end in order to seal the piping and stop the fluid.

Pipe Plug

It is a male Threaded Fittings for seal a tube or other pipe equipment. It can be divided into Hex Head Plug, Round Head Plug and Square Plug.

Hex Head Plug Dimension

| DN | NPS | WEIGHT(KG) |

|---|---|---|

| 6 | 1/8 | 0.02 |

| 8 | 1/4 | 0.05 |

| 10 | 3/8 | 0.08 |

| 15 | 1/2 | 0.12 |

| 20 | 3/4 | 0.2 |

| 25 | 1 | 0.34 |

| 32 | 1 1/4 | 0.59 |

| 40 | 1 1/2 | 0.73 |

| 50 | 2 | 1.44 |

| 65 | 2 1/2 | 2.36 |

| 80 | 3 | 3.5 |

| 100 | 4 | 6.08 |

Socket Weld Cap

Socket Weld End Caps comply with the standard ASME B16.11. They are available for small diameter piping system only. For the purpose of inserting the pipe into the cap, the diameter of cap should be a little larger than the pipe they match.

Caps are available in stainless steel, carbon steel and alloy steel. Stainless steel cap has outstanding corrosion resistance and good looking.

It has smooth appearance, high precision, high wear resistance and impact resistance, and it is not easily crushed by heavy objects.

They are suitable for small diameter with high pressure pipe system and food industry.

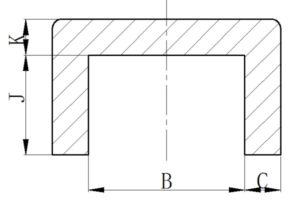

Socket Weld Cap

Socket Weld Cap Dimensions

| Diameter | 1/8inch to 4 inch, DN6-DN100 |

|---|---|

| Pressure | 3000#, 6000#, 9000# |

| Material | Stainless Steel: ASTM A182 F304/304L, F316/316L, F310 Carbon Steel: ASTM A105, A694 F42, F52, F60 Alloy Steel: ASTM A182 F1, F5, F11, F22, F91 |

What is ASME B16.11

This standard applies to Forged Socket Weld Fittings and Forged Threaded Fittings. These fittings are designated as Class 2000, 3000, and 6000 for threaded end fittings and Class 3000, 6000, and 9000 for socket-weld end fittings. B16.11 is to be used in conjunction with equipment described in other volumes of the ASME B16 series of standards as well as with other ASME standards, such as the Boiler and Pressure Vessel Code and the B31 Piping Codes.

ASME B16.11 Socket Weld Fittings

ASME B16.11 Forged Fittings include Socket Weld Elbow, Socket Weld Coupling, Socket Weld Tee, Socket Weld Cap, Socket Weld Union and Sockolet.

Pipes should be inserted into socket weld fittings and then welded.

The common manufacturing methods of the socket weld fittings are forging and stamping.

ASME B16.11 Socket Weld Fittings

Forged Fittings

Forged Fittings are impacted to get the shape. The products are compact, with good plasticity and mechanical properties. Due to the complex processing, the price is also higher.

The opposite of forgings is castings.

Casting Fittings

Castings are shaped by pouring metal liquid into a mold. It is relatively simple to make a pipe fitting with complicated shape in this way. But the mechanical properties of castings are lower than forgings.

Castings have low production costs and short processing time.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....