Forged Threaded Fittings

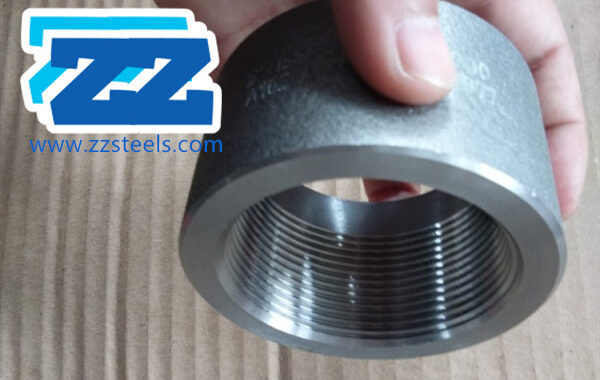

Singapore customers continually buy Forged Threaded Couplings from us. They are mostly ASTM A105 Half Coupling and SS316 Threaded Coupling.

Why always buy from us?Because they think our products are outstanding with high quality and competitive price. But how much do you know about Carbon Steel Half Coupling? Let’s go to see representative A105 Half Coupling.

What is Threaded Half Coupling?

Threaded Half Couplings are threaded only at one end, the other end is welded or fastened to pipes or fittings. In some areas people also call it Threaded Half Socket. It can be used in commercial and industrial environment to transfer water, oil, gas or air.

ASTM A105 Half Coupling is frequently used in hose connection except piping system. The threaded end is screwed onto a faucet, while the other end is clamped onto the hose. It is more suit for small diameter pipes with low pressure. Aerospace industry also uses half couplings as connectors for pressurized fuel piping.

Due to its extensive application, it is provided in various diameters and pressure ratings. Diameter is from 1/8” to 4” and pressure are 3000# and 6000#.

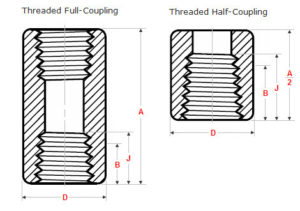

ASTM A105 Half Coupling Dimensions

The dimension of half coupling is same to full coupling except the length. Length is 1/2 of full coupling. We can get the data from below half coupling chart.

| Nominal Size | End-to-End | Outside Diameter | Length of Thread | |||

|---|---|---|---|---|---|---|

| L | D | |||||

| DN | NPS | 3000&6000 | 3000 | 6000 | L2 min | L5 min |

| 6 | 1/8 | 16 | 16 | 22 | 6.4 | 6.7 |

| 8 | 1/4 | 17.5 | 19 | 25 | 8.1 | 10.2 |

| 10 | 3/8 | 19 | 22 | 32 | 9.1 | 10.4 |

| 15 | 1/2 | 24 | 28 | 38 | 10.9 | 13.6 |

| 20 | 3/4 | 22.5 | 35 | 44 | 12.7 | 13.9 |

| 25 | 1 | 30 | 44 | 57 | 14.7 | 17.3 |

| 32 | 1 1/4 | 33.5 | 57 | 64 | 17.0 | 18.0 |

| 40 | 1 1/2 | 39.5 | 64 | 76 | 17.8 | 18.4 |

| 50 | 2 | 43 | 76 | 92 | 19.0 | 19.2 |

| 65 | 2 1/2 | 46 | 92 | 108 | 23.6 | 28.9 |

| 80 | 3 | 54 | 108 | 127 | 25.9 | 30.5 |

| 100 | 4 | 60.5 | 140 | 159 | 27.7 | 33.0 |

A105 Forged Pipe Fittings

Forged Couplings are designed for the industries which available in carbon steel, alloy steel and stainless steel. Usually A105 Half Coupling Threaded is the first choice. Why customers are interested so much? Let’s to know their function and advantage

Carbon Steel Material ASTM A105 covers Seamless Forged Carbon Steel Piping components for use in pressure systems at ambient and high-temperature service.

A105N Forged Fittings have good performance, less impurities, fine internal structure, and is not prone to defects, because forging process can change the metal structure and improve its mechanical properties.

Material A105 is for ASME B16.11 Forged Fittings, ASME B16.5 Flanges and MSS SP-97 Outlet.

ASTM A105 Half Coupling Chemical Composition

| C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.15max | 0.6-1.05 | 0.035 | 0.04 | 0.1min | 0.3 | 0.12 |

ASTM A105 Half Coupling Mechanical Properties

| Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) | Hardness |

|---|---|---|---|

| 485 | 250 | 30% | 187 |

BSP Threaded Fittings

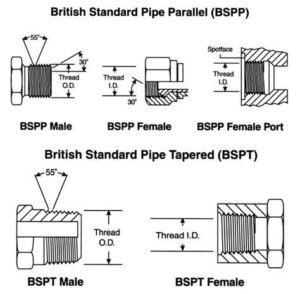

British Standard Pipe are shorten as BSP which threads come in two versions: parallel (BSPP), and tapered (BSPT).

While BSPT thread has a taper thread with 55 degree flank angle, which is the biggest difference with NPT thread. It has been adopted internationally for interconnection and sealing pipes and fittings. Its diameter increases or decreases along the thread length.

Compare with NPT Threaded Fittings, BSP Threaded Fittings are popular in Asia, Europe and UK. North America is rarely used unless the attachment is important. Male BSPT fittings should thread into a female BSPT fittings with 2 turns of thread sealant.

BSPP thread is parallel thread and often used in pressure systems on board ships.

BSPT Threads Dimension Chart

| Thread Size | Threads

Per Inch |

Pitch

mm |

Major Dia of the Thread | Gauge

Length mm |

|

|---|---|---|---|---|---|

| mm | in | ||||

| 1/16 | 28 | 0.907 | 7.723 | 0.304 | 4 |

| 1/8 | 28 | 0.907 | 9.728 | 0.383 | 4 |

| 1/4 | 19 | 1.337 | 13.157 | 0.518 | 6 |

| 3/8 | 19 | 1.337 | 16.662 | 0.656 | 6.4 |

| 1/2 | 14 | 1.814 | 20.995 | 0.825 | 8.2 |

| 5/8 | 14 | 1.814 | 22.911 | 0.902 | – |

| 3/4 | 14 | 1.814 | 26.441 | 1.041 | 9.5 |

| 1 | 11 | 2.309 | 33.249 | 1.309 | 10.4 |

| 1 1/4 | 11 | 2.309 | 41.91 | 1.65 | 12.7 |

| 1 1/2 | 11 | 2.309 | 47.803 | 1.882 | 12.7 |

| 2 | 11 | 2.309 | 59.614 | 2.347 | 15.9 |

| 2 1/2 | 11 | 2.309 | 75.184 | 2.96 | 17.5 |

| 3 | 11 | 2.309 | 87.884 | 3.46 | 20.6 |

| 4 | 11 | 2.309 | 113.03 | 4.45 | 25.5 |

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....