Alloy Steel Threadolet

More and more customers inquired about ASTM A182 F22 Threadolet. Why are they so interested? Let’s take a look at Alloy Steel Threadolet.

It is an outlet fittings that has been very popular overseas in recent years, we are global supplier of alloy steel threaded pipe outlets and exported to 30 countries.

Alloy Steel F22 Threadolet

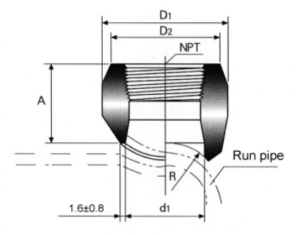

ASTM A182 F22 Threadolet is a Reinforced Branch Fitting (also called Branch Connection Fitting, Outlet Fitting or Olet Fitting) that provides 90 degree branch from a run pipe to a smaller pipe. One end is welded onto the run pipe and the other end is threaded to the smaller pipe. The welded end is usually called run or header and the other end is called branch.

Alloy Steel A182 Forged Branch Outlets Fittings is a big family including A182 F9 Weldolet, A182 F91 Sockolet, ASTM A182 F22 Threadolet, A182 F1 Nipolet, A182 F5 Latrolet, A182 F12 Elbowolet, Flexolet A182 F22, A182 F9 Insert Weldolet and A182 F91 Sweepolet.

A182 F22 Threadolet stands out of them because it facilitates installation.

MSS SP-97 Threadolet Branch Connection

Threadolet Branch Connection is screw female thread end to a male threaded pipe or fittings with sealant. And the thread type should keep in line, or they will not be sealed. Why it is so popular in the industries and people like them so much? Maybe it’s their advantage.

- Easy operation.

- Less work difficulty.

- Enhances efficiency.

What’s more, they are friendly connecting to small diameter pipes, because ASTM A182 F22 threadolet branch size range is from 1/4 inch to 4 inch only according to MSS SP-97 standard. And International thread types are BSP or NPT.

What is MSS SP-97

The full name is Integrally Reinforced Forged Branch Outlet Fittings- Socket Welding, Threaded, and Butt Welding Ends. Typically, pipe fittings are all forgings in this standard.

It covers essential dimensions, tolerances, finish, material, marking, and other requirements for 90 degree Reinforced branch fittings.

- Dimension

- Weldolet diameter range is from 1/8 to 24 inch and schedule are STD, XS, XXS, SSCH160. But for Sockolet and Threadolet, the size is 1/8” to 4” and pressure are 3000# and 6000#.

- Material

- They are all available in stainless steel, carbon steel, and alloy steel. Galvanizing and anti-rust oil coating are usually used on ASTM A105 Olet.

- Marking

- The marking should permanently marked with manufacture’s name, material, class, size and SP 97.

Class 3000 Threadolet Dimension

Threadolets are available in class 3000 and class 6000. 3000# ASTM A182 F22 threadolet is widely used in Oil and Gas Pipeline, Chemical Industry, Water Supply Systems, Power Plant and Heating.

| Run Pipes

Nominal Size |

Branch

Nominal Size |

Length | Fitting

OD |

Branch

End OD |

Thread

Length |

Cut Hole

Diameter |

|||

|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | DN | NPS | A | D1 min | D2 min | L2 min | d1 min | |

| 8-900 | 1/4-36 | 6 | 1/8 | 19 | 27 | 22 | 6.7 | 16 | |

| 10-900 | 2/8-36 | 8 | 1/4 | 19 | 27 | 22 | 10.2 | 16 | |

| 15-900 | 1/2-36 | 10 | 3/8 | 21 | 30 | 25 | 10.4 | 19 | |

| 20-900 | 3/4-36 | 15 | 1/2 | 25 | 38 | 33 | 13.6 | 24 | |

| 25-900 | 1-36 | 20 | 3/4 | 27 | 47 | 39 | 13.9 | 30 | |

| 32-900 | 1 1/4-36 | 25 | 1 | 33 | 56 | 48 | 17.3 | 36 | |

| 40-900 | 1 1/2-36 | 32 | 1 1/4 | 33 | 66 | 58 | 18.0 | 45 | |

| 50-900 | 2-36 | 40 | 1 1/2 | 35 | 75 | 64 | 18.4 | 51 | |

| 65-900 | 2 1/2-36 | 50 | 2 | 38 | 90 | 77 | 19.2 | 65 | |

| 80-900 | 3-36 | 65 | 2 1/2 | 46 | 105 | 94 | 28.9 | 76 | |

| 100-900 | 4-36 | 80 | 3 | 51 | 124 | 114 | 30.5 | 94 | |

| 125-900 | 5-36 | 100 | 4 | 57 | 154 | 140 | 33.0 | 121 | |

Tolerances: 1/8 – 1/4 ±7.62mm and 1 – 4 ± 15.24mm

Now, you get sufficient knowledge about threadolet, but it is not the end. Do not forget that material is the important. Let’s continues to know A182 F22.

What is ASTM A182?

ASTM A182/ SA182 is a standard specification for Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Valves and Parts for High Temperature Service. It covers low alloy and ferritic, martensitic, austenitic and ferritic-austenitic stainless steels piping components for pressure system application.

A182 F22 Forged Fittings

It is Chrome Moly Alloy steel containing nominally 2.25% Chromium. A182 F5, F11 and F91 are Chrome Moly Alloy steel in this standard as well.

This kind Alloy Steel Fittings have excellent resistance to hydrogen corrosion and high temperature, so it is widely used in Petroleum and Chemical industry and pressure vessels.

What’s the types of forged fittings, especially A182 F22 Fitting that are mostly Threaded F22 Elbow, ASTM A182 F22 Threaded Equal Tee, A182 F22 Socket Weld Coupling, Alloy Steel F22 Swage Nipple and A182 F22 Threaded Cap and Union.

F22 Forged Fittings Advantages

- Easy to be processed and show a beautiful appearance.

- It can be deeply quenched instead of the normal surface quenching.

- It is resistant for impact and hard to be damaged by violent.

- High temperature and high pressure resistance.

- Resistance to hydrogen corrosion.

- Easy to weld.

ASTM A182 F22 Threadolet Chemical Composition %

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.05-0.15 | 0.50 | 0.30-0.60 | 0.04 | 0.04 | 0.8-1.25 | 0.044-0.65 |

ASTM A182 F22 Threadolet Mechanical Properties

| Tensile Strength | Yield Strength/0.2 | Reduction of Area | Elongation |

|---|---|---|---|

| 415-515 Mpa | 205-310 MPa | 35% | 20% |

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....