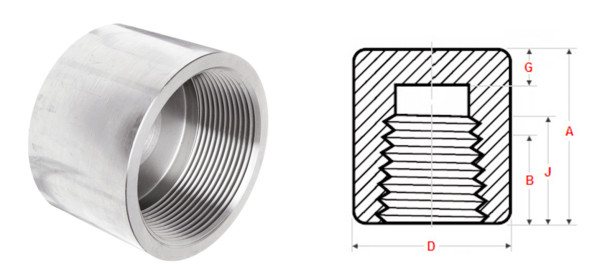

Threaded Caps for Pipe

SS 316 Threaded Cap is a forged ASME B16.11 pipe fittings that used to cap off conduit runs for future use. In most cases, it is a female (internal) thread fittings and connected to male (external) thread pipe to block off the flow. Threaded Plugs have the same function with it, but they are male thread fittings.

According to the standard ASME B16.11, Forged Pipe Caps are available in diameter NPS 1/8 to NPS 4, pressure Class 3000, Class 6000 and Class 9000. Therefore, they are commonly used in water and gas pipelines, small diameter water pipes, compressed air pipe systems and steam pipes.

Forged Threaded Pipe Fittings

We offered forged pipe fittings with fine internal organization and outstanding mechanical properties, can withstand high pressure. Its sealing is also very good with suitable glues (such as thick white paint, lead oxide glycerin glue, etc.). SS 316 Threaded Cap are ideal of use where there is exposure to chemicals and other types of corrosive products such as chloride which tends to cause pitting.

Compared to welding fittings, the most significant feature of threaded fittings is easy installation. When installation, it is no need to hire professional to welding, ordinary workers can do the job. It also has no requirements for working sites, even in the sites without electricity, gas, or exposed in open flames. Because it avoids the influences of artificial factors, the performance of SS 316 Threaded Cap is extremely stable.

SS UNS S31600 Forged Threaded Fittings

The thread of SS UNS 31600 Threaded Cap mostly are NPT and BSP. NPT is a tapered thread. Tapered BSP called BSPT, BSPP is parallel thread. The biggest difference between NPT and BSP is the angle across the flanks of threads, which is 55 degree and 60 degree, respectively.

In theory, the thread of ASME B16.11 Forged Fittings should comply with American National Standard for Pipe Threads ASME B1.20.1, which is NPT thread. But you can choose another thread type in consideration of your conditions and make a consensus with your manufacturers.

SS 316 Threaded Cap Fittings

Stainless steel Threaded Fittings is austenitic stainless steel fitting with high corrosion resistance and long service life. Stainless steel usually contains a high proportion of Cr and Ni, some contains over than 20% like SS310. SS 316 Threaded Cap has excellent strength and toughness as well, but the most prominent advantage is its high corrosion resistance, which makes it irreplaceable in corrosive environments such as chemical papermaking. Common used stainless steel grades are SS304/304L, SS316/316L, SS321, SS316 is the best one among them. They should be compiled to ASTM A182 for forging produce.

ASTM A182 F316 Forged Fittings Equivalent Grades

- Werkstoff NR. 1.4401/1.4436

- UNS S31600

- JIS S31600

- BS 316S31/316S33

SS 316 Threaded Cap Chemical Composition %

| C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.08 | 1.0 | 2.0 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

SS316 Threaded Cap Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|

| 515 (Mpa) | 205 (Mpa) | 30 (%) | 215 |

ASTM A182 Stainless Steel Threaded Fittings

A182 F316 Fittings have great toughness and durability. It can hold up to some of the worst environments with the beauty retained. It also has advantages in reducing the cost of clean, maintain and inspection, and decreases the downtime cost. Furthermore, the usage of SS 316 Threaded Cap contributes to LEED certification, which helps increase the value of a project. In addition, it has high scrap value when a project at its end. So the application of stainless steel pipe fittings is more common along with the awakening of environment and economic consciousness.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....