Carbon Steel Nipolet

ASTM A105 Nipolet is a one piece pipe fitting that can be used for valve take-offs, drains, vents or taps. It is a number of branch connection fittings family that is essentially a Weldolet with a nipple. Carbon steel are commonly used in Nipolet fabricating. The most general Carbon Steel is A105 Nioplet. It comes with either a plain or threaded end (PE or TE).

Olet Fittings

The body of Outlet Fittings are made of high quality forgings with the same material as the running pipe. The common manufacturing execution standards are MSS SP-97, ANSI/ASME B16.9, ANSI/ASME B16.11 and GB/T19326.

It has been widely used abroad in recent years for connecting reinforced fittings. It replaces the traditional reinforced connection method. Its advantages are outstanding, especially in large diameter, thick wall pipelines with high pressure and temperature.

Reinforced Fittings

The traditional branch reinforced fittings are Reducing Tees, reinforcing pad and reinforced pipe section, they are used in branch pipe connections.

Generally, branch are formed by cutting a hole in the side of pipe and welding another section of appropriately sized pipe on it. The metal removing leads to the stress concentration created. A “hole weakening” created on the pipeline.

In critical systems, this weakness must be compensated, and can be restored with a reinforcing fitting, to strengthen the piping branch connection or the pressure vessel nozzle.

Olet Fittings Types

The most common outlet fittings are Weldolet, Sockolet and Threadolet. But now we will mainly introduce special outlet fittings. ASTM A105 Nipolet for you.

-

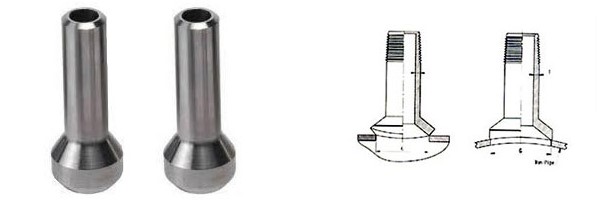

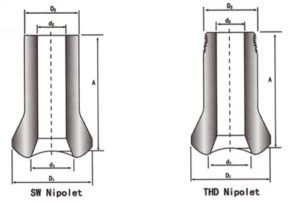

Nipolet

Available in schedule XS and XXS from 1/2″ to 4″.

-

Latrolet

A Latrolet is similar to a Weldolet that makes a 45 degree reducing branch on a straight run of pipe. Butt-weld Latrolet can meet specific reinforcement requirements, and socket weld and threaded Latrolet are only available in 3000LB or 6000 LB applications.

-

Elbolet

It is used on 90° long radius elbows, short radius elbows is not used often and can be used on 180° returns. It applies to thermowell and instrumentation connections. Which are butt weld, socket weld and threaded connections.

-

Sweepolet

It is a contoured, integrally reinforced butt weld outlet. It is suitable for low stresses and long fatigue life conditions.

-

Insert Weldolet

An Insert Weldolet is designed to be welded flush with the pipe.

MSS-SP-97 Olets Advantages

- Compared to traditional reinforced fittings, Olets facilitate fabrication and reduce cost since reducing cutting and welding. Weldolet fabricates and costs 50% to 90% less than welding tees.

- Maintain full pipe strength in accordance with MSS-SP-97.

- Provide full fluid flow and perfectly contoured internal joint.

- Avoid metal to metal lapped surfaces and sharp re-entrant corners.

ASTM A105 Nipolet Dimension Chart

ASTM A105 Nipolet Dimension Chart

| Run Pipes Nominal Size | Branch Nominal Size | Length | OD at End | OD of Fitting | Cut Hole Diameter | ||||

|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | DN | NPS | A | D2 | D1 | D1 | ||

| XS | SCH160 | XS | SCH160 | ||||||

| 20-900 | 3/4-36 | 15 | 1/2 | 89 | 21.3 | 38 | 47 | 24 | 19 |

| 25-900 | 1-36 | 20 | 3/4 | 89 | 26.7 | 47 | 53 | 30 | 25 |

| 32-900 | 1 1/4-36 | 25 | 1 | 89 | 33.4 | 56 | 63 | 36 | 33 |

| 40-900 | 1 1/2-36 | 32 | 1 1/4 | 89 | 42.2 | 66 | 72 | 45 | 38 |

| 50-900 | 2-36 | 40 | 1 1/2 | 89 | 48.3 | 75 | 83 | 51 | 49 |

| 65-900 | 2 1/2-36 | 50 | 2 | 89 | 60.3 | 90 | 104 | 65 | 59 |

| 80-900 | 3-36 | 65 | 2 1/2 | 89 | 73 | 105 | – | 76 | – |

| 90-900 | 3 1/2-36 | 80 | 3 | 89 | 88.9 | 124 | – | 94 | – |

| 125-900 | 5-36 | 100 | 4 | 89 | 114.3 | 154 | – | 121 | – |

As per purchase specification, the ends can be machined as plain or threaded type, and the thread shall be machined per ASME B1.20.1 equivalent to GB/T 12716.

A105 Forged Steel Fittings

A105 Forged Steel Fittings

ASTM A105 is the most common forged carbon steel material with excellent hardness. Most are supplied in a normalized state.

Normalizing is a heat treatment that improves the toughness of steel. The main feature is the cooling rate is faster than annealing and lower than quenching. During normalizing, the crystal grains can be refined in cooling, which not only helps obtain satisfactory strength, but also can significantly improve the toughness (AKV value), and reduce the tendency of crack. After normalizing, the overall mechanical properties of the carbon steel forged fittings can be greatly improved and the cutting performance is also enhanced.

ASTM A105 Nipolet Chemical Composition

| C | Mn | P | S | Si | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.15 | 0.6-1.05 | 0.035 | 0.04 | 0.1 | 0.3 | 0.12 |

ASTM A105 Nipolet Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 485 (Mpa) | 250 (Mpa) | 30 (%) |

How to Order Forged Nipolet

- Specify Size: Outlet size and Run pipe size.

- Specify Style: Butt Weld Nipolet, Socket Weld Nipolet, NPT Nipolet, PE Nipolet, TE Nipolet , Swage Nipple and Galvanized Nipolet.

- Indicate Class or Schedule/Pipe Wall: XS or XXS

- Select Material: ASTM A105 Nipolet, SS316 Nipolet, A182 F22 Nipolet

- Other: Specify Design Code (if available).

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....