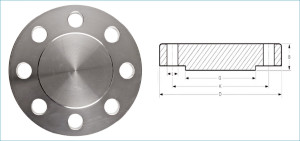

ASME B16.5 BLRF Flanges

ASME SA182 Alloy Steel Blind Raised Face Flange are advantage of durable and low cost that used in the pipelines with special demands, especially high temperature and pressure piping.

What is Blind Flange?

Forged Blind Flanges are usually applied in the end of pipe system, or the junction parts, for the purpose of block off pipelines. They are solid round steel plates with bolt holes and a seal face. That widely used in pressure and leak testing of pipe system, because of simple installation and easy dismantle. They also can be reused thereby avoiding waste and reducing the cost, especially for pipes that need to be repeatedly blocked.

Among pipe fittings, pipe plugs and caps have the same function as them. They can seal the pipe but not be dismantled. So flange connection is your first choice when you need a flexible way to block the piping.

Alloy Steel Blind Flange Dimensions

| Diameter | 1/2″ to 24″, DN 15 to DN 600 |

| Pressure | Class 150, 300, 600, 900, 1500, 2500 |

| Seal Type | FF, RF, RTJ, T&G, MFM |

| Seal Schedule | Sch 40, 80, 160, XXS |

| Alloy Steel Blind Flange | ASTM A182 F1, F11, F22, F5, F91 |

ASTM A182 Alloy Steel Flange

While it covers 18 grades, and we show you the common grades that usually used in industries. There are also other special grades like Nickel Alloy 200 or Hastelloy C22.

There are some types as below.

- Slip-on Flange

- Socket Weld Flange

- Weld Neck Flange

- Threaded Flange

- Blind Flange

- Lap Joint Flange

What is Alloy Steel?

Alloy steel Forged Flanges have better properties than general metal, its tensile strength, shear strength, density and thermal conductivity will be improved. It can satisfy various performance requirements based on the different combination of alloy elements.

Most of them have strong corrosion resistance, you can used them in chemical industries without troubled. Their seals are very tight and leak proof.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....