3000# Socket Weld Coupling

Socket weld coupling is a very short section of pipes with socket bore at both ends or one end, but both can afford high pressure of 3000#, 6000#, 9000#. We also called them as full and half coupling separately.

ISO certified manufacturer Zizi exports high quality socket weld coupling ASTM A105 / A105N ASME B16.11 to Nigeria. We store various sizes of socket weld pipe fittings in class 3000, 6000 and 9000.

Socket weld fittings have a recessed area for receiving inserted pipe and helping it align. Many pipe fittings have socket weld type, such as forged elbow, forged tee, pipe union, pipe coupling and forged cap.

Features of Socket Weld Fittings

- 3000# socket weld coupling is applied for small diameter pipe system

- High leakage integrity

- Great structural strength

- Lower fatigue resistance than butt weld fittings

- Can be used to flammable, toxic, high pressure and high temperature pipeline.

- Designed to provide good flow characteristics

- No need for alignment.

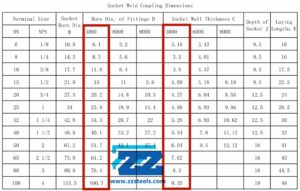

3000# SW Coupling Dimensions

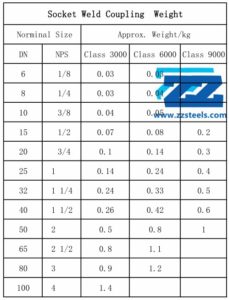

Socket Weld Coupling Weight

Material for Class 3000 Coupling

Stainless Steel: ASTM A182 F304/304L/304H, 316/316L/316H, 321, 310/310S, 317,347

Carbon Steel: ASTM A105/A105N 3000# coupling, A350 LF2/LF3, A694 F52, F65, F70

Alloy Steel: ASTM A182 F1, F5, F9, F11, F12, F22, F91

Duplex Steel: ASTM A182 F51, F53, F55, F60

Package of ASTM A105 Coupling

Brush anti rust oil and wrap plastic film for ASTM A105 Couplings

Carton and wooden cases for forged pipe fittings.

Inspection of 3000# Socket Weld Coupling

Check the surface

- Marking includes size, material, standard and Lot No., such as “SW Coupling 2” 3000# A105 ASME B16.11 ZZ379”. Be sure they are correct and clear.

- Touch and visual check the surface to ensure it is smooth and no flaws.

Measure the size

- Measure the size of outside diameter, socket bore diameter, bore diameter of fittings, wall thickness, depth of socket and laying lengths.

- Reference the tolerance table, confirm the sizes are in tolerance.

- Record the values of 3000# SW couplings.

Approve third party inspection

- Third parties such as BV, SGS, LR, DNV, ABS.

- Offer stamped Mill Test Certificate.

Application

- Gas Processing

- Power Generation

- Petrochemicals

- Chemical Equipment

ASTM A105N Properties

Chemical Compositon,%

| C | Mn | P | S | Si | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 0.35 | 1.05 | 0.035 | 0.04 | 0.35 | 0.4 | 0.3 | 0.12 |

Mechanical Properties

| Tensile Strength | Yield Strength | Elongation |

|---|---|---|

| 485 MPa | 250 MPa | 22 % |

此站点遇到了致命错误。